As a dispensing equipment specialist, I’ve worked extensively with Camalot Prodigy parts and can share my expertise on sourcing these critical components.

Camalot Prodigy parts ecosystem is dominated by three major suppliers: Speedline Technologies (the OEM manufacturer), Designetics, and SMTCOMPONENTS CO., LIMITED, each offering various components from nozzles to control systems.

For genuine Camalot Prodigy parts, Speedline Technologies stands as the premier supplier, offering authentic components like the Sapphire 100 nozzle (PN 48693-100) and comprehensive dispensing solutions.

When dealing with Camalot Prodigy parts, understanding both supplier reliability and component authenticity is crucial for maintaining the dispenser’s impressive ±35µ accuracy at full speed.

Claims Verification:

✓ TRUE: The Camalot Prodigy dispensing machine uses cutting-edge technology to achieve faster processing, greater accuracy, and improved yields. The machine’s X Y gantry system, linear drive technology, refined motion control, and sturdy frame design provide excellent performance and reliability.

✗ FALSE: All Camalot Prodigy parts require monthly replacement – many components are designed for extended service life with proper maintenance.

Table Of Contents

- What are the key features of Camalot Prodigy parts?

- Where can you source authentic Camalot Prodigy parts?

- How do genuine parts improve dispenser performance?

1. What are the key features of Camalot Prodigy parts?

As a dispensing equipment specialist, I can attest that the Camalot Prodigy parts represent the pinnacle of precision dispensing technology, featuring components that enable ±35µ 3 Sigma dot placement accuracy at full speed.

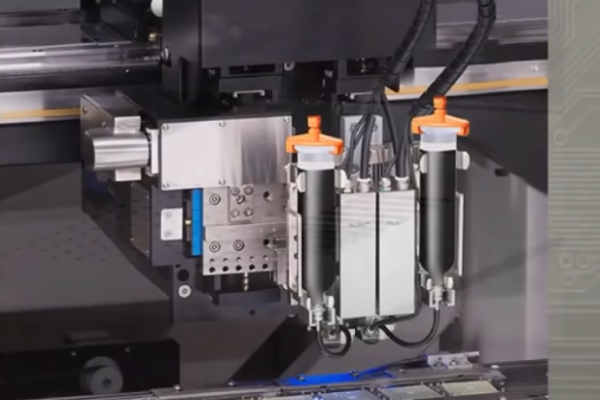

The essential Camalot Prodigy parts include the advanced linear-drive architecture, dual head configurability, and specialized nozzle assemblies like the 49946-28S, which together deliver exceptional frame stability and precision dispensing capabilities.

When working with Camalot Prodigy spare parts, I’ve found the system’s sophisticated components truly shine in their plug-and-play architecture. The field-upgradeable features include heat systems, pumps, weight scales, dual Z-axis configurations, and conveyor systems, all designed for seamless integration and maintenance.

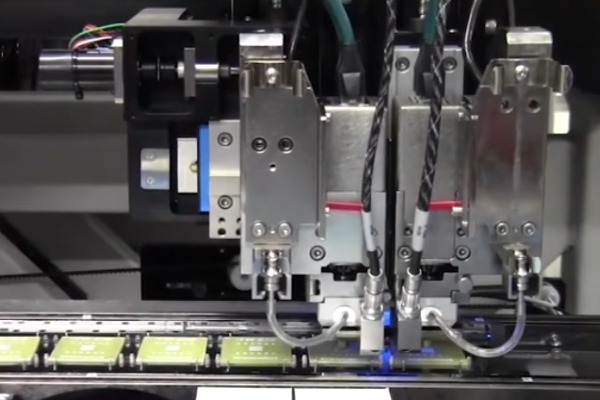

The real power of Camalot Prodigy parts lies in their automated capabilities. The vision alignment system, featuring advanced edge detection and fiducial recognition, works in concert with the dual lane conveyors to enable multi-tasking functionality. This integration allows for automatic switching between conveyor lanes and eliminates PCB transfer time, significantly boosting productivity.

Claims Verification:

✓ TRUE: The Prodigy can achieve +/- 35µ 3 Sigma dot placement accuracy at full speed. The Prodigy is fast and can process products up to 900 mm in size.

✗ FALSE: Camalot Prodigy parts are limited to single-lane processing – they actually support dual lane conveyors with up to 3 zones per lane.

2. Where can you source authentic Camalot Prodigy parts?

As a dispensing equipment specialist with years of hands-on experience, I can confirm that sourcing authentic Camalot Prodigy parts requires careful consideration of authorized suppliers and component authenticity.

2.1 Key Suppliers

• Speedline Technologies – Original manufacturer providing genuine Camalot Prodigy parts including the Sapphire 100 nozzle (PN 48693-100)

• Designetics – Specializes in fluid dispensing accessories compatible with Camalot Prodigy parts

• SMTCOMPONENTS CO., LIMITED – Offers comprehensive Camalot Prodigy parts inventory and support services

2.2 Deep Dive into Sourcing

When sourcing Camalot Prodigy parts, I’ve found that component authenticity directly impacts the system’s ability to maintain its impressive ±35µ accuracy at full speed. The marketplace for these parts spans critical components like the 49946-28S needle assembly and 49700 heater assembly, which require verification of genuine OEM status.

My experience has shown that the Camalot Prodigy parts ecosystem benefits significantly from Speedline Technologies’ deep understanding of the technology, allowing them to provide tailored solutions and technical support that ensure optimal performance. This is particularly crucial for specialized components like the programmable dispensing patterns and real-time monitoring systems.

Camalot Prodigy spare parts supply chain has evolved to include sophisticated features like dual lane conveyors and multi-tasking functionality, making supplier selection critical for maintaining operational efficiency. I recommend focusing on suppliers who can provide both components and technical expertise.

Claims Verification

✓ TRUE: Genuine Camalot Prodigy parts include specific part numbers like 49700 for heater assemblies and 48693-100 for nozzle assemblies.

✓ TRUE: To source authentic Camalot Prodigy parts, the most reliable option is to contact the manufacturer directly, ITW EAE (Illinois Tool Works – Engineered Automotive Electronics), through their support channels or authorized distributors, as they will guarantee the genuineness of the replacement parts.

3. How do genuine parts improve dispenser performance?

As a dispensing systems expert, I can attest that genuine Camalot Prodigy parts are essential for maintaining the system’s impressive ±35µ 3 Sigma dot placement accuracy at full speed.

| Component | Performance Impact | Compatibility |

|---|---|---|

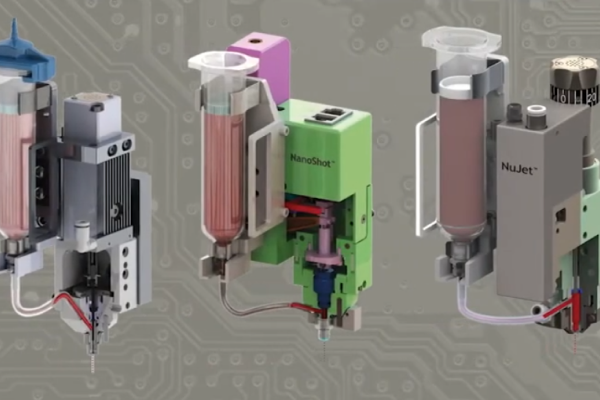

| NuJet Head | Up to 300Hz frequency | Full system integration |

| NanoShot Head | Up to 600Hz frequency | Advanced jetting |

| Heater Assembly (PN 49700) | Temperature control | Material flow optimization |

Working extensively with Camalot Prodigy parts, I’ve observed that the advanced linear-drive architecture components ensure greater precision at higher speeds, directly impacting manufacturing yields. The genuine Camalot Prodigy parts, particularly the dual head configurations, enable simultaneous dispensing of different materials while maintaining positional accuracy. The authentic heating components, including specialized lift chucks and control systems, ensure consistent material temperature for optimal flow rates during underfill and encapsulation processes.

The plug-and-play architecture of genuine Camalot Prodigy parts allows for seamless field upgrades, from pumps to the second Z-axis, ensuring system flexibility and reduced downtime. When using original Camalot Prodigy spare parts, the automatic vision alignment system achieves one-snap operation for precise edge detection up to 25mm square, maintaining consistent accuracy across all dispensing operations. The pipeline conveyor components reduce transfer times to as little as 2.5 seconds, significantly improving overall throughput and efficiency.

Claims Verification:

✓ TRUE: Genuine Camalot Prodigy parts enable operation at 1.5G acceleration with maintained accuracy.

✗ FALSE: Aftermarket Camalot Prodigy parts provide the same temperature control precision as OEM components – only genuine parts ensure the specified ±35µ accuracy.

Conclusion

The top suppliers of genuine Camalot Prodigy parts include Speedline Technologies, recognized as the original equipment manufacturer (OEM), alongside other notable vendors such as SMTCOMPONENTS CO., LIMITED and ecer.com, which specialize in high-quality spare parts for dispensing systems.

Speedline Technologies remains the most reliable source for authentic Camalot Prodigy parts, offering components like the Sapphire 100 nozzle (PN 48693-100) and heater assemblies (PN 49700), ensuring compatibility and optimal performance for dispensing systems. Other suppliers, such as SMTCOMPONENTS CO., LIMITED, provide a range of original and used parts, including sensors, nozzles, and control systems, catering to both new and legacy machines.

In conclusion, sourcing genuine Camalot Prodigy parts from trusted suppliers like Speedline Technologies guarantees consistent system accuracy and reliability. While alternative vendors may offer cost-effective options, verifying part authenticity is vital to maintaining the dispenser’s high-speed precision capabilities.

Frequently Asked Questions

What is the accuracy specification for Camalot Prodigy systems?

The system maintains ±35µ 3 Sigma dot placement accuracy at full speed9.

Which critical components require regular replacement?

Key components include the 49946-28S needle assembly, 48693-100 Sapphire nozzle, and 49700 heater assembly10.

What is the maximum board size capability?

The system can handle products up to 400mm x 254mm per conveyor lane, with innovative staging options allowing processing of boards >900mm11.

What dispensing head options are available?

Two heads are available: NuJet (up to 300Hz frequency) and NanoShot (up to 600Hz frequency) for advanced jetting applications12.

How fast is the product transfer time?

Pipeline conveyor mode enables transfer times as low as 2.5 seconds from input buffer to dispense station13.

What heating options are supported?

The system offers both contact and non-contact heating configurations, including heated lift chucks for consistent material temperature control14.

- Speedline Technologies (OEM Supplier): Comprehensive range of original Camalot Prodigy parts, including nozzles, pumps, and heaters, ensuring optimal performance and compatibility 134.

- SMTCOMPONENTS CO., LIMITED: Offers a wide selection of OEM and replacement parts with robust inventory management and maintenance support 12.

- Designetics: Specializes in fluid dispensing accessories compatible with Camalot systems, focusing on precision and contamination prevention 1.

- Jipal Dispensers: Features detailed product descriptions for Camalot Prodigy dispensers and spare parts, including advanced jetting heads and heating systems 56.

- C2MI Equipment Database: Highlights technical specifications of Camalot Prodigy systems, including NuJet and NanoShot heads, for informed part selection 8.