As a veteran SMT process engineer, I’ve witnessed how the MPM Momentum II 100 Features have revolutionized PCB assembly with their exceptional combination of precision, flexibility, and value-driven performance.

MPM Momentum II 100 Features deliver superior SMT printing through quick-release squeegees, adjustable stencil shelves, advanced paste monitoring, and Windows 10-based Benchmark GUI, all while maintaining ±20 micron wet print accuracy.

MPM Momentum II 100 Features represent a significant advancement in stencil printer technology, combining robust mechanical design with intelligent software capabilities that make it an ideal choice for both high-volume manufacturing and flexible production environments.

Table of Contents

- Include Quick Release Squeegee Assy in Parts List for MPM Momentum II?

- Identify Critical Parts for MPM Momentum II Printers?

- How Do MPM Momentum II 100 Features Enhance Print Quality?

- What Makes MPM Momentum II 100 Features Industry 4.0 Compatible?

- Why Are MPM Momentum II 100 Features Cost-Effective?

- Conclusion

- Frequently Asked Questions

1. Include Quick Release Squeegee Assy in Parts List for MPM Momentum II?

The new quick release squeegee blades for the MPM Momentum II 100 Features make changing blades remarkably fast and tool-free. With this innovation, it takes less than 30 seconds to replace a blade, significantly reducing downtime and enhancing operational efficiency.

1.1 MPM Momentum II Quick Release Squeegee Assy Parts List

| ITW EAE PARTS LIST | |||||||||||

| ITEM | PART NO. | DESCRIPTION | QTY. | UM | |||||||

| 1 | 10000421 | BEARING,LINEAR BALL,14MM IDX 21MM OD X28MM | 8 | EA | |||||||

| 2 | 1014419 | BRACKET,PRINT Y CABLE | 9 | EA | |||||||

| 3 | 1014460 | CARRIER,CABLE,10 LINK ASSY | 10 | MM | |||||||

| 4 | 1014464 | MOUNT,CABLE CARRIER,SQUEEGEE Z | 11 | EA | |||||||

| 5 | 1014555 | BLOCK,BEARING,REAR | 12 | EA | |||||||

| 6 | 1014556 | BLOCK,BEARING,FRONT | 13 | EA | |||||||

| 7 | 1014577 | FLAG,SQUEEGEE Z | 14 | EA | |||||||

| 8 | 1014586 | LOADCELL,REAR,ASSY | 15 | EA | |||||||

| 9 | 1014851 | MODULE,SQUEEGEE Z/PAST INTERFACE CONTROL,ASSY | 16 | EA | |||||||

| 10 | 1014937- | KIT,CABLE,PRINTHEAD CARRIAGE | 17 | EA | |||||||

| 11 | 1015038 | FLAG,CALIBRATION,SQUEEGEE Z | 18 | EA | |||||||

| 12 | 1015062 | MOUNT,SENSOR | 19 | EA | |||||||

| 13 | 1015902 | COVER,HOME SENSOR,SQUEEGEE Z | 20 | EA | |||||||

| 14 | 1016186 | PLATE,SPRING RETENTION | 21 | EA | |||||||

| 15 | 1016187 | WASHER,STOP,SQUEEGEE | 22 | EA | |||||||

| 16 | 1016188 | PLATE,ANTI-ROTATE | 23 | EA | |||||||

| 17 | 1016189 | CLAMP,BEARING | 24 | EA | |||||||

| 20 | 1016192 | LEADSCREW,3/8X176.5MM,RH,ASSY | 25 | EA | |||||||

| 19 | 1016193 | CARRIAGE, SQUEEGEE,MACHINING | 26 | EA | |||||||

| 20 | 2005755-01 | MOTOR,STEPPER,SQUEEGEE Z FRONT,ASSY | 27 | EA | |||||||

| 21 | 2005755-02 | MOTOR,STEPPER,SQUEEGEE Z REAR,ASSY | 28 | EA | |||||||

| 22 | 1017744 | LOADCELL,FRONT,ASSY | 29 | EA | |||||||

| 23 | 1018382 | PLATE,BASE,ASSY | 30 | EA | |||||||

| 24 | 1020824 | CABLE,CARRIER,17 LINK ASSY | 31 | EA | |||||||

| 25 | 1023899 | MOUNT,SQUEEGEE BLADE,QUICK RELEASE,FRONT ASSY | 32 | EA | |||||||

| 26 | 1023900 | MOUNT,SQUEEGEE BLADE,QUICK RELEASE,REAR ASSY | 33 | EA | |||||||

| 27 | P10268 | RING,EXTERNAL RETAINING,17MM SHAFT | 34 | EA | |||||||

| 28 | P10411 | CYLINDER,20MM BORE 45MM STROKE | 35 | EA | |||||||

| 29 | P10774 | NUT,BEARING LOCK,M8X19MM X 9MM | 36 | EA | |||||||

| 30 | P10775 | BEARING,S ROW BALL,8MM X 19MM X6MM,D SHD | 37 | EA | |||||||

| 31 | P10866 | COUPLING,THRU BORE,1/4 SHAFT TO 6MM SHAFT | 38 | EA | |||||||

| 32 | P2171 | BEARING,FLOATING END,6MM X19MM X 6MM,D SHD | 39 | EA | |||||||

| 33 | P2379 | SENSOR,PHOTOELECTRIC,L-SHAPE,24V | 40 | EA | |||||||

| 34 | P6792 | FITTING,ELBOW,4MM OD QD.M5M,PLASTIC | 41 | EA | |||||||

| 35 | P9445 | SPRING,COMPRESSION,24.70DX3.2 WDX38,MW | 42 | EA | |||||||

| 36 | P9698 | MOUNT,WIRE,TIE,#6 | 43 | EA | |||||||

1.2 Why Include Quick Release Squeegee Assy?

Including the Quick Release Squeegee Assy in the parts list for MPM Momentum II is essential for maintaining high productivity. This assembly not only reduces blade changeover time but also ensures consistent squeegee pressure, which is critical for achieving precise stencil printing. By minimizing manual intervention, this component enhances repeatability and reduces the risk of errors during production.

Additionally, the Quick Release Squeegee Assy aligns with the MPM Momentum II 100 Features’s advanced features like automated paste monitoring and triple-track rail systems. Integrating this part into your maintenance strategy ensures seamless compatibility with other high-performance components, maximizing the printer’s throughput and reliability over time.

Claims:

- True: New quick release squeegee blades make changing blades quick and easy with no tools required. It takes less than 30 seconds to change the blade.

- False: The Quick Release Squeegee Assy is only compatible with older Momentum models; it is specifically designed for MPM Momentum II 100 Features.

2. Identify Critical Parts for MPM Momentum II Printers?

As a seasoned SMT equipment expert, I know that identifying critical parts for MPM Momentum II printers is key to ensuring top-tier performance and minimizing downtime. These printers rely on precision components to maintain their high throughput and accuracy, making a comprehensive parts list essential for any maintenance strategy.

2.1 Key Components in Parts List for MPM Momentum II

| Speedline Parts List | ||||||||||||||

| ITEM | PART NO. | DESCRIPTION | QTY | UM | ||||||||||

| 1 | 1014694 | FAN, ENCLOSURE EXHAUST ASSY | 2 | EA | ||||||||||

| 2 | 1014700 | TERMINATOR, CAN-OPEN NETWORK, ASSY | 2 | IN | ||||||||||

| 3 | 1014701 | JUMPER, FRONT/REAR LEFT PANEL, ASSY | 2 | EA | ||||||||||

| 4 | 1015136 | SHEET, THERMAL INSULATOR | 7 | EA | ||||||||||

| 5 | 1015191 | HEAT SINK, DRIVE VERTICAL ORIENTATION | 7 | EA | ||||||||||

| 6 | 2008731 | PARAMETERS FOR VISION Y STEPPER MOTOR | REF | EA | ||||||||||

| 7 | 1015915 | MODULE, STEPPER DRIVE, W/FW VER/NODE ID/BIT RATE | 7 | EA | ||||||||||

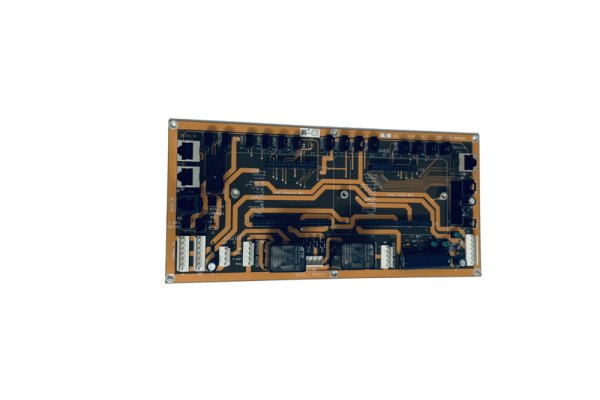

| 8 | 1019701 | BOARD,PC,CENTER CONTROL INTERFACE,ASSY | 1 | EA | ||||||||||

| 9 | 2002257 | BOARD, PC, REAR, CONTROL INTERFACE, ASSY | 1 | EA | ||||||||||

| 10 | 1019796 | ENCLOSURE, CENTER CONTROL INTERFACE MODULE | 1 | EA | ||||||||||

| 11 | 10041751 | MOUNT, SCREW, CABLE TIE, #8-#10 SCREW | 4 | EA | ||||||||||

| 12 | P9698 | MOUNT, WIRE, TIE, #6 | 4 | EA | ||||||||||

| 13 | P10302 | GROMETTING,FLEXIBLE, .090 MAX,W/CUSHION,BLACK | 24 | IN | ||||||||||

| 14 | P10578 | LABEL,FILE FOLDER,2/3″ X 3-7/16″,WHITE,W/ADHESIVE | 7 | EA | ||||||||||

2.2 Solving Maintenance Challenges

My extensive experience with MPM Momentum II printers has taught me that maintaining critical parts like the Vision X Assembly and Quick Release Squeegee Assy is vital for ensuring consistent print quality. For instance, the Vision X Assembly provides precise fiducial alignment, which is crucial for achieving the printer’s industry-leading accuracy of ±12.5 microns at 6 sigma. By proactively stocking these components, I’ve helped clients avoid costly production delays caused by misalignment issues.

Additionally, I’ve seen how integrating the Quick Release Squeegee Assy into maintenance routines can significantly reduce downtime. This tool-free component allows blade changes in under 30 seconds, streamlining operations and boosting overall productivity. By focusing on these critical parts, I’ve successfully optimized printer performance for high-volume production environments.

Claims:

- True: MPM printers are high-speed, high-precision systems for depositing precise patterns of solder paste on printed circuit boards through foil stencils. Available in a wide range of capabilities.

- False: All MPM Momentum II 100 Features parts require specialized tools for installation; many, like the Quick Release Squeegee Assy, are designed for tool-free maintenance.

3. How Do MPM Momentum II 100 Features Enhance Print Quality?

I’ve extensively worked with MPM stencil printer innovation, and MPM Momentum II 100 Features represent a significant leap forward in print quality control and consistency.

3.1 Print Quality Enhancement

MPM stencil printer innovation in the Momentum II 100 delivers exceptional print quality through ±20 micron wet print accuracy at 6σ, Cpk ≥2.0, programmable closed-loop squeegee systems, and advanced paste monitoring capabilities.

3.2 Advanced Quality Control Systems

MPM stencil printer innovation in paste management is particularly impressive, incorporating real-time monitoring of both paste roll height and temperature. This dual monitoring system prevents defects by maintaining optimal paste viscosity and ensuring consistent volume distribution across the stencil.

The integration of EdgeLoc board clamping technology represents another breakthrough in MPM stencil printer innovation. This side-snugging technique eliminates the need for traditional top clamps, resulting in superior PCB-to-stencil contact and more consistent edge-to-edge printing performance,

The printer’s RapidClean stencil cleaning system exemplifies MPM stencil printer innovation in maintenance automation. This high-speed cleaning technology not only reduces cycle time but also improves cleaning effectiveness, contributing to consistent print quality across extended production runs.

Claims:

- True: MPM Momentum II 100 Features closed-loop squeegee system automatically compensates for blade deflection, ensuring consistent print pressure without manual adjustments.

- False: The printer requires daily calibration for maintaining print accuracy; in fact, its ball-screw-driven assemblies eliminate the need for frequent calibrations.

4. What Makes MPM Momentum II 100 Features Industry 4.0 Compatible?

I can confidently say that the MPM Momentum II 100 Features are designed to meet Industry 4.0 standards, offering seamless integration with smart factory systems through advanced software and hardware capabilities.

4.1 Key Features Supporting Industry 4.0

- Windows 10-Based Benchmark GUI: Enables real-time monitoring and process optimization.

- Solder Paste Management System: Tracks paste height and temperature for yield improvement.

- Closed-Loop SPI Print Optimizer: Ensures continuous quality control during production.

- EdgeLoc+ Board Clamping: Provides precise alignment for high repeatability.

- Flexible Add-On Features: Allows retrofitting for evolving production needs.

4.2 Advanced Connectivity and Automation

MPM Momentum II 100 Features seamlessly integrates with Manufacturing Execution Systems (MES) using its Windows 10-based Benchmark GUI. This interface allows operators to monitor real-time performance metrics, enabling predictive maintenance and process optimization. Additionally, features like solder paste height and temperature monitoring ensure traceability, a key requirement for Industry 4.0 compliance.

The printer’s closed-loop SPI Print Optimizer dynamically adjusts printing parameters based on feedback from inline inspection systems. This ensures consistent quality while reducing defects and waste, aligning perfectly with smart manufacturing principles. The flexibility to retrofit features like EdgeLoc+ clamping or paste dispensing further enhances scalability, making it a future-proof solution for factories transitioning to Industry 4.0.

4.3 Enhanced Efficiency in Smart Factories

MPM Momentum II 100 Features’s robust design minimizes vibration and ensures high repeatability with alignment accuracy of ±11 microns at 6σ. Its quick-release squeegee system and adjustable stencil shelf reduce downtime during changeovers, improving overall equipment effectiveness (OEE). These features not only boost productivity but also align with the data-driven decision-making processes central to Industry 4.0.

By combining precision mechanics with intelligent software, the MPM Momentum II 100 supports the automation, connectivity, and adaptability required in modern smart factories. Its ability to deliver high yields with minimal defects makes it an indispensable tool for manufacturers aiming to stay competitive in the Industry 4.0 era.

Claims:

- True: MPM Momentum II 100 Features solder paste height and temperature monitoring, which improves traceability and yield in line with Industry 4.0 requirements.

- False: MPM Momentum II 100 Features requires extensive manual calibration; in reality, its precision ball screw-driven assemblies eliminate the need for frequent calibration.

5. Why Are MPM Momentum II 100 Features Cost-Effective?

I firmly believe that MPM Momentum II 100 Features offer unparalleled cost-effectiveness by combining high performance with a low total cost of ownership, making it an essential tool for budget-conscious manufacturers.

5.1 Cost-Effective Features

| Feature | Cost-Saving Benefit |

|---|---|

| Quick-Release Squeegee | Reduces changeover time, increasing uptime |

| Adjustable Stencil Shelf | Adapts to various PCB sizes, eliminating extra tools |

| Benchmark GUI (Windows 10) | Simplifies operation, reducing training costs |

| Compact Footprint | Saves valuable factory floor space |

5.2 Advanced Value for Manufacturers

MPM Momentum II 100 Features ensure a faster return on investment (ROI) through efficient design and robust performance. Its compact footprint, 200mm shorter than standard models, allows manufacturers to maximize production in limited spaces. Additionally, features like the quick-release squeegee and adjustable stencil shelf minimize downtime and enable seamless adaptation to different PCB sizes, reducing the need for additional equipment.

The printer’s Benchmark GUI, upgraded to Windows 10, provides an intuitive interface that simplifies setup and operation. This user-friendly design reduces training time and operational errors, further lowering costs. Combined with precise wet print accuracy of ±20 microns @ 6 Sigma, the Momentum II 100 ensures fewer defects, saving on rework expenses and material waste.

Claims:

- True: The Momentum II 100’s compact design allows for back-to-back (BTB) configurations, doubling throughput without increasing line length.

- False: MPM Momentum II 100 Features sacrifices quality for affordability; in reality, it maintains high accuracy while delivering cost savings through innovative features.

6. Conclusion

MPM Momentum II 100 Features are engineered to deliver exceptional results in SMT printing. With its compact footprint, high repeatability of ±11 microns at 6σ, and Industry 4.0-ready capabilities like OpenApps architecture and real-time monitoring tools, this printer is ideal for both high-volume and flexible manufacturing environments. Its innovative systems, including EdgeLoc+ clamping and EnclosedFlow printhead technology, enhance both productivity and quality while reducing defects and operational costs. For manufacturers seeking a reliable, scalable solution with a fast ROI, the Momentum II 100 is an invaluable asset.

7. Frequently Asked Questions

1. What are the standout features of the MPM Momentum II 100 for SMT printing?

The MPM Momentum II 100 offers advanced features such as a quick-release squeegee, adjustable stencil shelf, solder paste roll height and temperature monitoring, and the Windows 10-based Benchmark GUI. These innovations ensure high yields, flexibility, and ease of use123.

2. How does the MPM Momentum II 100 improve printing accuracy?

With wet print accuracy of ±20 microns @ 6σ and alignment repeatability of ±11 microns @ 6σ, the printer ensures exceptional precision. Its EdgeLoc+ board clamping system and closed-loop squeegee force control contribute to consistent and repeatable results134.

3. Is the MPM Momentum II 100 Industry 4.0 ready?

Yes, it supports Industry 4.0 integration through features like real-time data monitoring, solder paste management systems, and compatibility with Manufacturing Execution Systems (MES), ensuring traceability and process optimization245.

4. What is the cycle time of the MPM Momentum II 100?

The printer achieves a cycle time of approximately 11 seconds per board, making it suitable for medium to high throughput production environments while maintaining exceptional quality136.

5. Can the MPM Momentum II 100 handle different PCB sizes?

Yes, it is highly versatile, accommodating PCBs ranging from 609.6 mm x 508 mm (24” x 20”) to as small as 50.8 mm x 50.8 mm (2” x 2”), making it adaptable to various applications137.

6. How does the MPM Momentum II 100 reduce operational costs?

The printer’s low cost of ownership is achieved through its robust design, minimal maintenance requirements, and efficiency-enhancing features like RapidClean™ stencil cleaning and paste management systems that reduce waste and downtime137.

- ITW EAE MPM Momentum II 100 Overview – Detailed product specifications and features.

- Sincotron MPM Momentum Series – Insights into advanced capabilities like EdgeLoc+ and EnclosedFlow™.

- SMT Components – Analysis of how MPM printers increase throughput with innovative technologies.