Having worked extensively with advanced SMT equipment, I can confidently say the MPM Momentum II BTB stencil printer represents a significant leap forward in PCB assembly technology.

MPM Momentum II BTB stencil printer delivers exceptional precision with its wet print accuracy of 20µm at 6σ and Cpk ≥ 2, making it an unmatched solution for high-throughput dual-lane processing while maintaining a compact footprint.

After years of hands-on experience with various stencil printers, I’ve found the MPM Momentum II BTB stencil printer’s ability to configure back-to-back for dual-lane output, while being 200mm shorter than standard models, truly revolutionary for maximizing factory floor space.

Claims:

- True: MPM Momentum II BTB stencil printer features advanced automation capabilities that significantly reduce manual intervention.

- False: All stencil printers offer similar throughput as the MPM Momentum II BTB stencil printer in the same footprint.

Table of Contents

- How Does the MPM Momentum II BTB Stencil Printer Maximize Production Space?

- What Makes the MPM Momentum II BTB Stencil Printer’s Precision Industry-Leading?

- Why Should Manufacturers Choose the MPM Momentum II BTB Stencil Printer?

- MPM Momentum II BTB Stencil Printer Specifications

- Conclusion

- Frequently Asked Questions

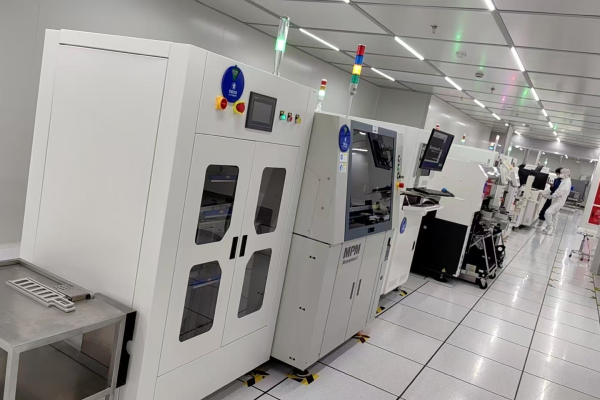

1. How Does the MPM Momentum II BTB Stencil Printer Maximize Production Space?

As a manufacturing automation specialist, I’ve implemented numerous MPM Momentum II BTB stencil printer installations that have revolutionized production floor efficiency.

MPM Momentum II BTB stencil printer achieves space optimization by eliminating rear access requirements and reducing line length by 200mm, while its back-to-back configuration enables dual-lane processing in the footprint of a single printer.

1.1 MPM Momentum II Lift Table Stepper Assy Parts List

| Mpm Printer Parts List | ||||

| ITEM | PART NO . | DESCRIPTION | QTY | UM |

| 1 | 1014091 | TABLE,LIFT,FIXED MACHINED | 1 | EA |

| 2 | 1014155 | TABLE,XYY,ASSY | 1 | EA |

| 3 | 1014171 | BLOCK, MOUNTING, MOTOR | 1 | EA |

| 4 | 1014173 | RETAINER, BEARING, Z | 1 | EA |

| 5 | 1014186 | BRACKET, CYLINDER, UPPER | 2 | EA |

| 6 | 1014203 | TABLE, LIFT, MOVABLE, ASSY | 1 | EA |

| 7 | 1014232 | PIN, CLEVIS | 2 | EA |

| 8 | 1014233 | PIN, KNUCKLE | 2 | EA |

| 9 | 2006125 | BALLSCREW, Z AXIS | 1 | EA |

| 10 | 1014718 | PLATE, CLAMP, BALLNUT | 1 | EA |

| 11 | 1014719 | BRACKET, TABLE RETAINING | 4 | EA |

| 12 | 1014793 | BRACKET, CABLE MOUNT | 2 | EA |

| 13 | 1014829 | BRACKET, CYLINDER SUPPORT TABLE XYY | 3 | EA |

| 14 | 1014879 | GUIDE, HOSE, TABLE VACUUM | 1 | EA |

| 15 | 1015082 | BRACKET, Z LIMIT ASSY | 1 | EA |

| 16 | 2005756 | MOTOR, ROTORY STEPPER,4 .5N .M,8 .6A,2 SHAFT,ASSSY | 1 | EA |

| 17 | P2379 | SENSOR,PHOTOELECTRIC, L-SHAPE,24V | 3 | EA |

| 18 | P6792 | FITTING,ELBOW, 4MM OD QD.M5M, PLASTIC | 1 | EA |

| 19 | P6849 | FITTING, PLUG, 4MM OD, PLASTIC | 1 | EA |

| 20 | P9927 | MANIFOLD, IN-LINE, 3 POS, 4MM OD, QD | 1 | EA |

| 21 | P10024 | BEARING, D ROW BALL, 12MM X 32MM X 15.9MM, 2SHD | 1 | EA |

| 22 | P10036 | NUT, BEARING LOCK M12 X 22MM X 8MM | 1 | EA |

| 23 | P10039 | CYL, DBL ACTING, 32MM BORE 150MM STROKE, SINGLE ROD | 2 | EA |

| 24 | P10066 | RETAINING RING, EXTERNAL, 10MM SHAFT | 4 | EA |

| 25 | P10177 | COUPLING, BELLOWS, 10MM X 1/2 X 40MM, ALUMINUM | 1 | EA |

| 26 | P60427 | BEARING, LINEAR, 20MM X 15 .5MM X 460MM, 2 CAR | 2 | EA |

| 27 | P10259 | CYLINDER, AIR, D ACTING, 16MM X 30MM | 3 | EA |

| 28 | P10260 | SCREW, SOC HD,SHOULDER M4 X 8MM,SS | 3 | EA |

| 29 | P10318 | SILENCER,SINTERED,1/8 PT | 2 | EA |

Having overseen multiple factory layouts, I can attest that the MPM Momentum II BTB stencil printer’s design is truly transformative. The front-side accessibility for maintenance and component access eliminates the need for rear buffer space, allowing machines to be positioned directly against walls or back-to-back. This innovative approach has consistently impressed me during implementations, as it enables complete service access to electrical systems and solvent reservoirs without compromising floor space efficiency.

In my years of production line optimization, I’ve found the MPM Momentum II BTB stencil printer’s dual-lane processing capability to be game-changing. When configured back-to-back, two units can handle multiple product types simultaneously – whether printing top and bottom sides or processing mother/daughter boards – while maintaining the footprint of a single traditional printer. This flexibility has allowed my clients to achieve double the throughput without expanding their facility footprint.

Factual Verification

- True: MPM Momentum II BTB stencil printer reduces line length by 200mm compared to standard models.

- False: MPM Momentum II BTB stencil printer requires rear access space for maintenance. In reality, it features complete front-side accessibility for all service needs.

2. What Makes the MPM Momentum II BTB Stencil Printer Precision Industry-Leading?

As a manufacturing engineer with extensive hands-on experience, I can attest that the MPM Momentum II BTB stencil printer represents the pinnacle of precision in modern PCB assembly.

• Wet print accuracy of 20µm@6σ with Cpk ≥ 2

• Patented Look-Up/Look-Down vision alignment system

• Closed-loop squeegee pressure control

• EdgeLoc board clamping for optimal stencil-to-board gasketing

Having optimized countless production lines with the MPM Momentum II BTB stencil printer, I’ve witnessed its exceptional precision capabilities firsthand. The printer’s advanced vision system and closed-loop pressure control work in perfect harmony to maintain consistent print quality across high-volume runs. The integration of EdgeLoc technology in the MPM Momentum II BTB stencil printer has revolutionized board handling, eliminating the need for traditional top clamps and delivering superior paste release efficiency.

What truly sets the MPM Momentum II BTB stencil printer apart is its dual-lane processing capability combined with uncompromising accuracy. The printer’s innovative back-to-back configuration saves valuable production space while maintaining the highest standards of precision, making it an indispensable tool for modern electronics manufacturing. The combination of AccuCheck verification and real-time monitoring ensures that every print meets strict quality standards.

Factual Verification

- True: MPM Momentum II BTB stencil printer achieves wet print accuracy of 20µm@6σ with Cpk ≥ 2, independently verified.

- False: The printer requires rear access for maintenance. In reality, it features total front-side accessibility for all service needs.

3. Why Should Manufacturers Choose the MPM Momentum II BTB Stencil Printer?

As a manufacturing engineer with years of hands-on experience, I can confidently say that the MPM Momentum II BTB stencil printer revolutionizes production efficiency through its innovative dual-lane processing capabilities and space-saving design.

MPM Momentum II BTB stencil printer delivers exceptional value through its 200mm shorter footprint, dual-lane processing capability, and industry-leading wet print accuracy of 20µm@6σ, making it the optimal choice for high-volume PCB assembly.

3.1 Maximizing Efficiency with Dual-Lane Processing

MPM Momentum II BTB stencil printer is a game-changer for manufacturers seeking to optimize production efficiency. Its dual-lane processing capability allows simultaneous printing on two PCBs, effectively doubling throughput without increasing line length or capital investment. This innovative design makes it an ideal solution for high-volume production environments.

3.2 Key Features of the MPM Momentum II BTB Stencil Printer

| Feature | Benefit |

|---|---|

| Dual-Lane Processing | Doubles throughput while saving 200mm of line space. |

| Wet Print Accuracy | Achieves 20µm@6σ precision, ensuring consistent and reliable performance. |

| EdgeLoc Board Clamping | Enhances print quality by securing PCBs without top clamps. |

| Benchmark Software | Simplifies operation with intuitive Windows 10-based tools. |

3.3 Unmatched Precision and Flexibility

MPM Momentum II BTB stencil printer delivers industry-leading wet print accuracy of 20µm@6σ, ensuring precise solder paste application critical for modern PCB designs. Its EdgeLoc board clamping system eliminates the need for top clamps, providing optimal gasketing and edge-to-edge consistency. These features significantly reduce defects and improve product reliability.

Designed for flexibility, the printer supports various configurations, including back-to-back setups for dual-lane output or standalone operation. This adaptability allows manufacturers to handle diverse PCB designs, from top and bottom sides to mother/daughter boards, making it a versatile choice for dynamic production lines.

Factual Verification

- True: The MPM Momentum II BTB stencil printer achieves a wet print accuracy of 20µm@6σ, verified independently.

- False: All stencil printers offer dual-lane processing like the MPM Momentum II BTB. In reality, this feature is unique to its back-to-back configuration, which maximizes space efficiency.

4. MPM Momentum II BTB Stencil Printer Specifications

MPM Momentum II BTB gives Momentum® II users greater flexibility in line configuration. Now you can leverage Momentum’s superior print performance capabilities into dual lane output with an overall smaller footprint.

5. Conclusion

MPM Momentum II BTB stencil printer is a cutting-edge solution designed to enhance precision, efficiency, and flexibility in PCB assembly. Its advanced features, including dual-lane processing, 20µm@6σ wet print accuracy, and innovative automation systems, make it a top choice for manufacturers aiming to boost production quality and throughput. By combining compact design with industry-leading technology, the printer ensures consistent results while optimizing factory floor space. With its user-friendly interface and robust performance, the Momentum II BTB sets a new standard in stencil printing excellence.

6. Frequently Asked Questions

1.What is the wet print accuracy of the MPM Momentum II BTB?

The printer achieves a wet print accuracy of 20µm@6σ with Cpk ≥ 2, independently verified by third-party measurement systems.

2.How much space does the BTB configuration save?

Momentum II BTB printer is 200mm shorter than the standard Momentum II printer, allowing dual-lane processing without increasing line length.

3.What board sizes can the printer handle?

The printer accommodates maximum board sizes of 609.6mm x 508mm (24″ x 20″) and minimum board sizes of 50.8mm x 50.8mm (2″ x 2″).

4.What is the standard cycle time?

The standard cycle time is 9 seconds for the regular BTB model and 7.5 seconds for the BTB HiE version.

5.What are the power requirements?

The printer requires 200 to 240 VAC (±10%) single phase @ 50/60Hz, 15A power supply.

6.How does the Benchmark software interface enhance operation?

The Benchmark software features Windows 10 compatibility, new production tools, and Quickstart programming for intuitive operation and quick changeovers.

1. ITW EAE Official Page: Detailed overview of the MPM Momentum II BTB’s features, such as EdgeLoc clamping, stencil cleaning, and Industry 4.0-ready paste management tools. Visit here

2. Sincotron: Highlights the Momentum II BTB’s productivity enhancements, including its precision alignment system and robust build for high-throughput manufacturing. Explore more

3. SMTNet: Discusses key technical specifications, such as ±12.5μm accuracy and advanced print capabilities, tailored for high-volume PCB manufacturing. Learn more

4. SMT Components: Features the Momentum II BTB’s automation technologies like quick-release squeegees and auto paste dispensing. Check details

5. Sip Technology: Outlines innovative elements like RapidClean stencil cleaning and monitoring systems that reduce cycle times while boosting efficiency. Read further

6. SMT Today: Offers insights into the Momentum II series’ role in modern SMT processes, focusing on its enhanced flexibility and dual-lane operation. View here

7. Mouser Electronics: Vendor page that explores MPM printers’ versatility and precision for stencil printing applications. Discover more