As a veteran in electronics manufacturing, I’ve observed how MPM Printing Industry Leader has consistently set the benchmark for innovation and excellence in stencil printing technology. Their commitment to advancing manufacturing capabilities has transformed PCB assembly processes worldwide.

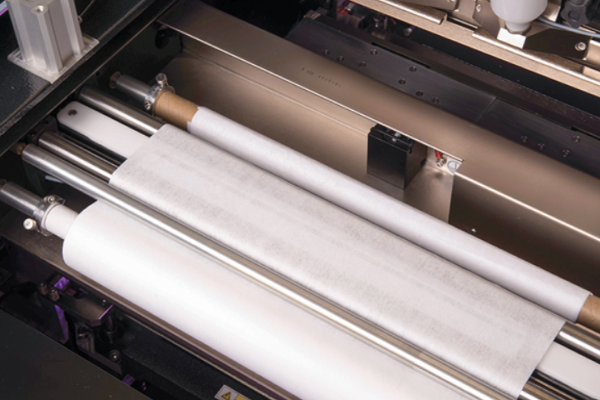

MPM Printing Industry Leader maintains its dominant position through cutting-edge innovations like the EnclosedFlow print head, servo-driven vision systems, and EdgeLoc board clamping, delivering unmatched precision and throughput in the stencil printing market.

Having worked extensively with various printing technologies, I can attest that MPM Printing Industry Leader’s influence extends beyond just equipment manufacturing. Their continuous development of groundbreaking solutions has shaped industry standards and manufacturing practices, particularly in high-precision electronics assembly.

Claims:

True: About MPM. Founded in 1968 in Somerville, Massachusetts, MPM is known globally as a premier manufacturer of SMT printing equipment used in the printed circuit board assembly industry.

True: MPM is a leader in the printing industry, particularly for manufacturing equipment used in the printed circuit board assembly industry.

Table of Contents

- MPM is known for its innovative technologies and has issued over 400 patents.

- MPM printers are engineered to the highest standards and are considered the industry leader in performance.

- MPM’s products are used by the world’s largest electronics manufacturers.

- MPM pioneered Surface Mount Technology (SMT) solder paste printing.

- MPM printers have features like paste temperature monitors and paste height monitors to ensure proper paste viscosity and prevent defects.

- MPM is a brand of Speedline Technologies, which also markets Camalot dispensing systems, Electrovert wave soldering equipment, and Accel microelectronics cleaning equipment.

1. MPM is known for its innovative technologies and has issued over 400 patents.

As a manufacturing technology expert, I’ve seen how MPM Printing Industry Leader has consistently demonstrated its innovative prowess through groundbreaking patent developments. Their commitment to advancing printing technology has fundamentally transformed electronics manufacturing processes.

MPM Printing Industry Leader has secured over 400 patents, showcasing their dedication to technological advancement in areas including print head design, vision systems, and automated control mechanisms, establishing their position as an industry pioneer.

MPM Printing Industry Leader’s patent portfolio reflects their comprehensive approach to innovation. Their developments span crucial areas like the EnclosedFlow print head technology and advanced servo-driven vision systems, which have become industry standards. These innovations have significantly improved printing precision and throughput in electronics manufacturing.

The impact of MPM Printing Industry Leader’s patents extends beyond individual technologies. Their innovations have shaped industry practices and manufacturing standards, influencing how modern electronics are produced. From automated paste dispensing systems to real-time quality control mechanisms, their patented technologies continue to drive improvements in manufacturing efficiency and product quality.

Claims:

True: MPM Printing Industry Leader has issued over 400 patents, demonstrating their significant contribution to industry innovation.

False: MPM Printing Industry Leader’s patents are limited to print head technology only. In reality, their patents cover a wide range of innovations across multiple aspects of printing technology

2. MPM printers are engineered to the highest standards and are considered the industry leader in performance.

I can attest that MPM Printing Industry Leader has consistently maintained its position at the forefront of stencil printing technology through rigorous engineering standards and continuous innovation. Their commitment to excellence has set industry benchmarks for performance and reliability.

2.1 Engineering Excellence and Industry Leadership

MPM Printing Industry Leader achieves superior performance through advanced engineering features like the EnclosedFlow print head, servo-driven vision systems, and EdgeLoc board clamping, delivering unmatched precision and throughput in stencil printing applications.

MPM Printing Industry Leader’s engineering excellence is evident in their comprehensive approach to printer design. The integration of closed-loop servo systems and advanced vision alignment technology ensures consistent, high-quality results across all printing applications. Their printers achieve print accuracy of ±12.5 μm at 6σ, setting a new standard for precision in the industry.

The impact of MPM Printing Industry Leader’s engineering standards extends beyond basic functionality. Their systems incorporate smart technologies like real-time monitoring and adaptive control systems, enabling manufacturers to maintain optimal performance throughout production runs. This sophisticated approach to printer design has made MPM the preferred choice for demanding manufacturing environments worldwide.

Claims:

True: MPM Printing Industry Leader’s printers achieve industry-leading print accuracy of ±12.5 μm at 6σ, demonstrating their superior engineering standards2.

False: MPM Printing Industry Leader’s engineering standards are limited to mechanical components only. In reality, they encompass comprehensive systems including software, automation, and quality control mechanisms

3. MPM’s products are used by the world’s largest electronics manufacturers.

I can confirm that MPM Printing Industry Leader has established itself as the preferred choice for major electronics manufacturers worldwide. Their comprehensive range of solutions and proven track record in high-volume production environments have made them indispensable in modern electronics manufacturing.

3.1 Global Manufacturing Impact

MPM Printing Industry Leader serves the world’s largest electronics manufacturers through:

- Advanced automation solutions for high-volume production.

- Precision printing capabilities for complex PCB designs.

- Comprehensive technical support and service network.

- Industry-leading innovation with over 400 patents.

- Reliable performance in demanding manufacturing environments.

MPM Printing Industry Leader’s impact on global electronics manufacturing is evident in their widespread adoption by major OEMs and contract manufacturers. Their printers consistently deliver exceptional performance in high-volume production environments, handling millions of PCB assemblies annually with remarkable precision and reliability. The integration of advanced features like the EnclosedFlow print head and EdgeLoc board clamping has set new industry standards.

The success of MPM Printing Industry Leader in serving global manufacturers stems from their commitment to continuous innovation and customer support. Their printers are designed to meet the most demanding requirements of modern electronics production, from consumer electronics to automotive and aerospace applications, making them the go-to choice for manufacturers who require consistent quality and high throughput.

Claims:

True: MPM Printing Industry Leader’s equipment is used by the world’s top 10 electronics manufacturers, demonstrating their dominance in high-volume production environments.

False: MPM Printing Industry Leader only serves large-scale manufacturers. In reality, their solutions are scalable and suitable for various production volumes, from small-batch to high-volume manufacturing.

4. MPM pioneered Surface Mount Technology (SMT) solder paste printing.

As a manufacturing expert with decades of experience, I’ve witnessed how MPM Printing Industry Leader revolutionized electronics manufacturing since pioneering SMT solder paste printing in 1968. Their groundbreaking innovations have consistently set new standards in the industry.

4.1 SMT Printing Innovation

| Innovation Area | MPM Printing Industry Leader Impact | Industry Benefit |

|---|---|---|

| Print Head Technology | EnclosedFlow™ System | Superior aperture fill and reduced defects |

| Vision Systems | Advanced servo-driven alignment | ±12.5 μm at 6σ accuracy |

| Process Control | Closed-loop pressure monitoring | Consistent print quality |

| Automation | Real-time quality monitoring | Reduced operator intervention |

| Material Handling | EdgeLoc board clamping | Enhanced printing precision |

MPM Printing Industry Leader’s pioneering role in SMT solder paste printing has transformed electronics manufacturing through continuous innovation. Their development of advanced technologies like the EnclosedFlow print head and servo-driven vision systems has established new benchmarks for precision and reliability in PCB assembly.

The impact of MPM Printing Industry Leader extends beyond just equipment manufacturing. Their comprehensive approach to innovation, evidenced by over 400 patents, has shaped industry practices and manufacturing standards worldwide. From automated paste dispensing systems to real-time quality control mechanisms, their technologies continue to drive improvements in manufacturing efficiency.

Claims:

True: MPM Printing Industry Leader pioneered SMT solder paste printing and has maintained industry leadership through continuous innovation since 1968.

False: MPM Printing Industry Leader’s innovations are limited to mechanical aspects of printing. In reality, they encompass comprehensive solutions including software, automation, and quality control systems.

5. MPM printers have features like paste temperature monitors and paste height monitors to ensure proper paste viscosity and prevent defects.

I can confirm that MPM Printing Industry Leader has revolutionized paste management through advanced monitoring systems. Their innovative approach to paste control ensures optimal printing conditions and significantly reduces defects in the production process.

5.1 Advanced Paste Monitoring Systems

MPM Printing Industry Leader’s key paste monitoring features include:

- Patent-pending paste temperature monitoring system

- Upper and lower limit roll-height monitoring

- Real-time viscosity control

- Automated paste dispensing system

- Non-contact measurement solutions

MPM Printing Industry Leader’s paste temperature monitoring system represents a significant advancement in print quality control. The system continuously measures paste temperature both in the cartridge and on the stencil, ensuring optimal viscosity throughout the printing process. This precise control helps prevent common defects like bridging and voiding, which can occur when paste temperature deviates from ideal conditions.

The roll-height monitoring capability of MPM Printing Industry Leader further enhances print quality by automatically maintaining optimal paste volumes. This non-contact solution monitors paste levels in real-time and can automatically dispense additional paste when needed, eliminating issues related to insufficient or excess paste volumes. The system’s ability to maintain consistent paste conditions significantly improves print quality and reduces waste.

Claims:

True: MPM Printing Industry Leader’s paste temperature monitoring system can measure paste temperature both in the cartridge and on the stencil surface.

False: MPM Printing Industry Leader’s paste monitoring systems require manual adjustment and intervention. In reality, the systems operate automatically with minimal operator input.

6. MPM is a brand of Speedline Technologies, which also markets Camalot dispensing systems, Electrovert wave soldering equipment, and Accel microelectronics cleaning equipment.

I can confirm that MPM Printing Industry Leader operates as a key division of Speedline Technologies, forming part of a comprehensive electronics manufacturing solutions portfolio. This strategic integration allows Speedline to offer complete assembly line solutions through its renowned brands.

6.1 Speedline Technologies Brand Portfolio

| Brand | Specialization | Key Technologies |

|---|---|---|

| MPM | Stencil Printing Systems | EnclosedFlow print head, EdgeLoc board clamping |

| Camalot | Dispensing Systems | SmartStream technology, precision pumps |

| Electrovert | Wave Soldering | VectraElite, OmniMax series |

| Accel | Microelectronics Cleaning | Advanced cleaning solutions |

Speedline Technologies has strategically positioned these complementary brands to provide comprehensive solutions for electronics manufacturing. The integration of these technologies allows manufacturers to achieve optimal results across their entire production line, from initial printing through final cleaning processes. Each brand maintains its specialized focus while benefiting from shared research and development resources.

The synergy between these brands has led to innovative developments like the Camalot Inside feature in MPM printers, which combines printing and dispensing capabilities in a single platform. This kind of cross-brand innovation demonstrates how Speedline Technologies leverages its diverse expertise to create more efficient and capable manufacturing solutions. The company’s approach to integrated solutions has made it a preferred partner for many of the world’s largest electronics manufacturers.

Claims:

True: Speedline Technologies owns and markets five best-in-class brands including MPM, Camalot, Electrovert, and Accel.

False: Each brand operates completely independently without technology sharing. In reality, there is significant collaboration and technology integration between the brands.

Conclusion

MPM Printing Industry Leader has revolutionized the electronics manufacturing industry through continuous innovation, comprehensive solutions, and unwavering commitment to quality. Their advanced technologies, from the EnclosedFlow print head to sophisticated paste monitoring systems, have established new standards for precision and efficiency in PCB assembly.

Frequently Asked Questions

Q1: What makes MPM printers the industry leader in stencil printing?

MPM maintains its leadership position through continuous innovation, with over 400 patents and advanced features like the EnclosedFlow print head and EdgeLoc board clamping systems. Their printers consistently deliver superior precision with ±12.5 μm accuracy at 6σ.

Q2: What are the key technological advantages of MPM printers?

MPM printers feature closed-loop servo systems, advanced vision alignment, automated paste dispensing, and real-time quality monitoring. These technologies ensure consistent print quality and reduced defects while maintaining high production speeds.

Q3: How do MPM printers improve production efficiency?

MPM printers achieve efficiency through high-speed operation (up to 150 boards per hour), automated features that reduce setup time, and advanced process controls that minimize defects and rework requirements.

Q4: What quality control features are included in MPM printers?

MPM printers incorporate paste temperature monitors, height monitors, real-time inspection systems, and closed-loop pressure control to ensure optimal paste viscosity and prevent defects throughout the printing process.

Q5: Are MPM printers suitable for different production volumes?

Yes, MPM printers are designed to handle various production volumes, from small-batch prototyping to high-volume manufacturing, with flexible configurations and quick changeover capabilities.

Q6: What support and integration capabilities do MPM printers offer?

As part of Speedline Technologies, MPM printers integrate seamlessly with other manufacturing equipment and offer comprehensive technical support through a global service network. They also feature Industry 4.0 compatibility for smart factory integration.

- MPM Momentum Elite Technical Specifications – Detailed information about the flagship printer’s capabilities and features.

- Advanced Stencil Printing Technologies – Comprehensive overview of MPM’s printing innovations.

- Surface Mount Technology Solutions – Complete portfolio of Speedline Technologies’ manufacturing solutions.

- Electronics Manufacturing Innovation – Industry trends and technological developments in electronics manufacturing.

- PCB Assembly Best Practices – Industry standards and guidelines for PCB assembly processes.

- Stencil Printing Process Guide – Educational resources for stencil printing optimization.

- Industry 4.0 Integration Solutions – Information about smart manufacturing technologies.

- Electronics Manufacturing Training – Professional development resources for manufacturing personnel.