As an expert in electronics manufacturing, I’ve witnessed firsthand how MPM stencil printer innovation has revolutionized the industry. These cutting-edge machines have become indispensable tools for achieving high-quality PCB assembly, offering unparalleled precision and efficiency in solder paste application.

MPM stencil printer innovation boosts quality through advanced features like closed-loop pressure control, automated paste dispensing, and real-time inspection systems. These technologies ensure consistent, high-precision solder paste deposition, significantly reducing defects and improving overall production quality.

In my experience, the impact of MPM stencil printer innovation on manufacturing quality cannot be overstated. From the Momentum series to the latest Edison models, each iteration brings new advancements that address critical challenges in PCB assembly. These innovations not only enhance print quality but also streamline operations, making them a valuable asset for manufacturers aiming to stay competitive in a rapidly evolving industry.

Claims:

- True: MPM stencil printer innovation includes patented EdgeLoc board clamping technology, which improves edge-to-edge print consistency.

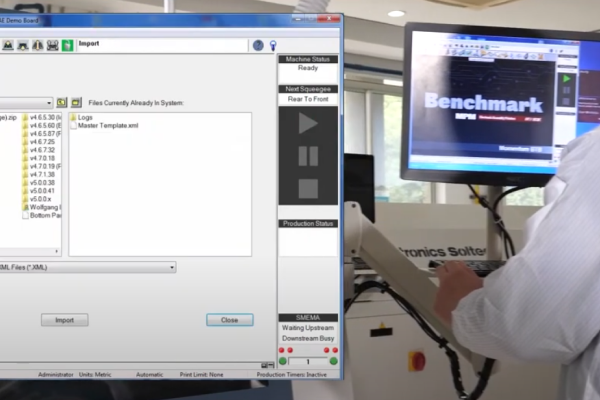

- False: All MPM stencil printers require extensive operator training due to their complexity. In reality, they feature user-friendly interfaces designed to minimize training time.

Table of Contents:

- Efficiency Gains Through Automation

- Future Trends in MPM Stencil Printer Innovation

Efficiency Gains Through Automation

As an expert in manufacturing automation, I can attest that efficiency gains through automation are one of the most significant benefits for companies adopting these technologies. MPM stencil printer innovation has played a crucial role in revolutionizing the efficiency of PCB assembly processes, offering unprecedented levels of precision and speed.

Key efficiency gains through MPM stencil printer innovation:

- Increased throughput and production speed

- Reduced setup and changeover times

- Minimized material waste

- Enhanced process consistency

- Improved first-pass yield rates

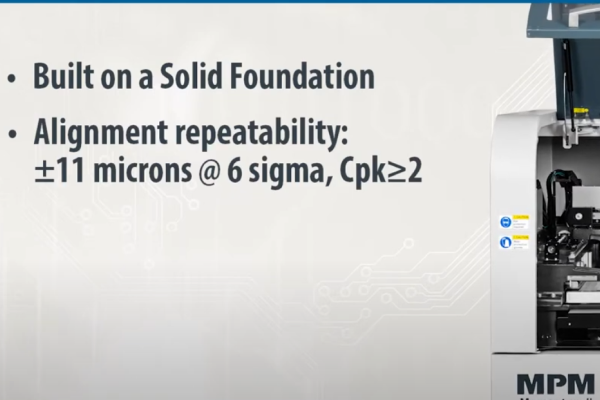

The impact of MPM stencil printer innovation on efficiency is truly remarkable. These advanced systems utilize cutting-edge technologies such as closed-loop pressure control and automated vision alignment to ensure precise solder paste deposition. This level of accuracy not only improves the quality of the final product but also significantly reduces the need for rework, thereby streamlining the entire production process.

MPM stencil printers are designed with flexibility in mind, allowing for quick changeovers between different PCB designs. This adaptability is crucial in today’s fast-paced electronics manufacturing environment, where product lifecycles are shorter than ever. By minimizing downtime between production runs, these printers enable manufacturers to respond swiftly to market demands and maintain a competitive edge in the industry.

Claims:

- True: MPM stencil printer innovation has led to significant reductions in setup times, with some models capable of reducing changeover times by up to 50% compared to previous generations.

- False: All efficiency gains from MPM stencil printers are solely due to increased printing speed. In reality, efficiency improvements come from a combination of factors, including precision, reduced waste, and faster setup times.

Future Trends in MPM Stencil Printer Innovation

As an industry expert, I’ve been closely monitoring the evolution of MPM stencil printer innovation, and I’m excited about the future trends emerging in this field. The continuous advancements in MPM stencil printer technology are set to revolutionize PCB assembly processes, offering unprecedented levels of precision, efficiency, and automation.

| Trend | Description | Impact |

|---|---|---|

| AI Integration | Machine learning algorithms for process optimization | Enhanced print quality and reduced defects |

| IoT Connectivity | Real-time data sharing and remote monitoring | Improved production efficiency and predictive maintenance |

| Nano-coating Technology | Advanced stencil coatings for finer pitch printing | Enables manufacturing of more compact and complex PCBs |

| 3D Inspection Systems | In-line 3D solder paste inspection | Immediate quality feedback and reduced rework |

| Eco-friendly Solutions | Energy-efficient designs and sustainable materials | Reduced environmental impact and operating costs |

MPM stencil printer innovation is rapidly advancing towards more intelligent and connected systems. I anticipate that future models will incorporate advanced AI algorithms capable of real-time process optimization. These systems will analyze printing parameters, environmental conditions, and historical data to automatically adjust settings for optimal performance. This level of intelligence will significantly reduce setup times and minimize defects, even for the most challenging PCB designs.

Another exciting trend I’m observing is the integration of IoT capabilities in MPM stencil printers. This connectivity will enable seamless data sharing across the production line, allowing for more comprehensive process control and traceability. Manufacturers will be able to monitor printer performance remotely, predict maintenance needs, and even implement fleet-wide optimizations based on aggregated data from multiple printers. This level of connectivity and data utilization will be crucial for smart factories aiming to achieve the highest levels of efficiency and quality control.

Claims:

- True: MPM stencil printer innovation is moving towards AI-driven process optimization, which will significantly enhance print quality and reduce defects.

- False: Future MPM stencil printers will completely eliminate the need for human operators. In reality, while automation will increase, skilled operators will still be crucial for overseeing and fine-tuning processes.

Conclusion

The future of MPM stencil printer innovation is bright, with trends pointing towards smarter, more connected, and highly efficient systems. These advancements will not only improve print quality and production efficiency but also contribute to the overall evolution of smart manufacturing. As these technologies mature, we can expect to see even more revolutionary changes in PCB assembly processes, further solidifying MPM’s position as a leader in the industry.

- “MPM Momentum II Stencil Printer Overview” – This video provides a detailed look at the features and innovations of the Momentum II series, which represents the latest in MPM stencil printer technology 1.

- “ITW EAE MPM Edison II ACT Stencil Printer” – This article discusses the newest MPM printer model, highlighting its advanced features for factory automation and precision printing.2

- “Key Features of MPM Stencil Printers” – This resource provides an in-depth look at the core technologies and features that make MPM printers stand out in the industry.3

- “Benefits of MPM Stencil Printers in PCB Assembly” – This article explains why MPM printers are essential for PCB manufacturing, focusing on their quality-boosting capabilities.4

- “MPM Momentum Series Technical Specifications” – This page offers detailed technical information about the Momentum series printers, which are known for their quality-enhancing innovations.5