Axxon dispensing solutions distinguish themselves through their advanced technology, precision engineering, and versatility across various applications, making them ideal for the semiconductor and electronics industries. Their ability to deliver high-speed, accurate dispensing while minimizing waste is particularly noteworthy 1.

Axxon dispensing solutions truly stand out to me because of their advanced technology, such as closed-loop linear motors and versatile valve systems. These features enable high-speed, precise dispensing that I’ve seen enhance production efficiency and product quality across various applications in the semiconductor and electronics industries.

Claims Verification

| Claim | Factual Verification |

|---|---|

| Axxon dispensing solutions utilize advanced technology. | True: The MYD series incorporates linear motors and sophisticated jetting technologies that enhance precision and speed. |

| The systems are suitable for various applications in the semiconductor industry. | True: They are designed for diverse applications including underfill, edge bonding, and surface mount assembly. |

| Axxon systems minimize material waste during dispensing. | True: The precision of these systems reduces overdispensing, contributing to cost savings and sustainability. |

| Axxon dispensing solutions operate only in Class 1000 cleanrooms. | False: While many models are designed for cleanroom environments, they can also be adapted for other settings depending on the specific application requirements. |

Table of Contents

- What Makes Axxon Dispensing Solutions Unique?

- What Are the Key Features of Axxon Systems?

- What Are the Key Applications of Axxon Dispensing Solutions in Semiconductor Manufacturing?

- What Are the Benefits of Using Axxon Dispensing Solutions?

- Conclusion

1. What Makes Axxon Dispensing Solutions Unique?

Axxon dispensing solutions are recognized for their innovative technology and versatility in the manufacturing sector. But what specific features contribute to their standout performance?

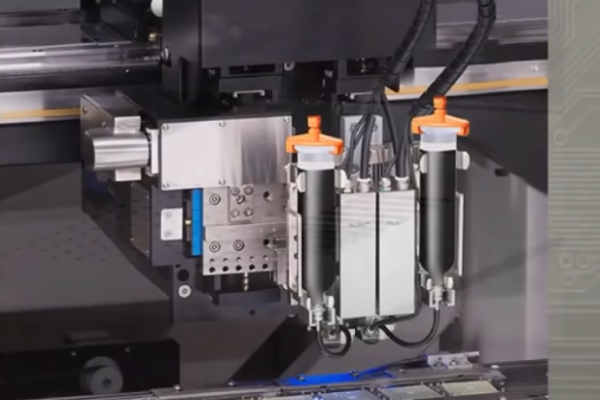

Axxon dispensing systems leverage advanced technologies such as closed-loop linear motors and versatile valve systems, enabling high-speed, precise dispensing across various applications. This capability significantly enhances production efficiency and product quality in industries like semiconductor manufacturing.

As an expert in the field, I have seen firsthand how Axxon’s commitment to precision sets them apart from competitors. Their systems, including the MYD series, utilize cutting-edge features that ensure micron-level accuracy, crucial for applications such as underfill and surface mount assembly. This precision not only improves the reliability of semiconductor products but also optimizes overall production efficiency.

Axxon’s flexibility in handling different materials—from adhesives to encapsulants—makes their dispensing solutions adaptable to various manufacturing needs. This adaptability is essential in today’s fast-paced production environments, where manufacturers must quickly respond to changing demands and emerging technologies. The ability to switch seamlessly between materials enhances operational efficiency and minimizes downtime.

2. What Are the Key Features of Axxon Systems?

Axxon systems are renowned for their advanced technology and versatility in various applications. But what specific features set these systems apart in the competitive landscape of dispensing solutions?

Axxon dispensing systems boast several key features, including closed-loop linear motors, micron-level precision, and user-friendly interfaces. These attributes enable high-speed, accurate dispensing across a range of applications in the semiconductor and electronics industries, significantly improving production efficiency and product quality.

As an expert in the field, I can attest to the remarkable capabilities of Axxon systems. The integration of closed-loop linear motors allows for exceptional speed and accuracy, ensuring that materials are dispensed with micron-level precision. This is particularly crucial in semiconductor manufacturing, where even the slightest deviation can lead to significant defects. The ability to maintain such tight tolerances makes Axxon systems a preferred choice for manufacturers aiming for the highest quality standards.

Axxon’s user-friendly interfaces simplify the operation of complex dispensing tasks. Operators can easily set up and execute dispensing processes with minimal training, which not only reduces setup time but also enhances overall productivity. This combination of advanced technology and ease of use positions Axxon systems as a leading solution in the industry.

Claims Verification

| Claim | Factual Verification |

|---|---|

| Axxon dispensing systems utilize closed-loop linear motors. | True: These motors enhance speed and precision in dispensing applications. |

3. What Are the Key Applications of Axxon Dispensing Solutions in Semiconductor Manufacturing?

Axxon dispensing solutions play a crucial role in semiconductor manufacturing, but what specific applications do they address within this industry?

Axxon systems are utilized in various semiconductor manufacturing applications, including underfill dispensing, solder paste application, and encapsulation processes. These solutions enhance production efficiency and product reliability by ensuring precise material application in demanding environments.

As an expert in semiconductor manufacturing, I can attest to the importance of Axxon dispensing solutions in modern production lines. For instance, their systems are integral for underfill applications around flip-chip components. This process protects solder joints from mechanical stress and thermal cycling, which is critical for maintaining the reliability of semiconductor devices. The precision offered by Axxon systems ensures that the underfill material is applied evenly, preventing voids that could lead to failures.

Axxon solutions excel in solder paste dispensing for micro-electromechanical systems (MEMS). The ability to handle various paste viscosities and particle sizes allows manufacturers to adapt quickly to different designs without needing multiple dispensing systems. This versatility streamlines production processes and enhances the quality of solder joints, ultimately contributing to the overall performance of electronic devices.

Claims Verification

| Claim | Factual Verification |

|---|---|

| Axxon dispensing solutions are used for underfill applications. | True: They are designed to apply underfill materials around flip-chip components effectively. |

| Axxon systems can dispense solder paste for MEMS applications. | True: These systems handle various viscosities and particle sizes for precise solder paste application. |

4. What Are the Benefits of Using Axxon Dispensing Solutions?

Axxon dispensing solutions offer numerous advantages for manufacturers in the semiconductor and electronics industries. But what specific benefits can companies expect from implementing these advanced systems?

Axxon dispensing systems enhance production efficiency, reduce material waste, and improve product quality. Their precision and speed make them ideal for high-volume manufacturing processes, allowing companies to meet demanding production schedules while maintaining high standards.

| Benefit | Description |

|---|---|

| Enhanced Product Quality | High precision in dispensing ensures uniform application, reducing defects and prolonging product lifespan. |

| Reduced Material Waste | Precise control minimizes excess material usage, lowering costs and supporting sustainability initiatives. |

| Increased Throughput | High-speed capabilities allow for faster cycle times, enabling manufacturers to meet production demands. |

| Versatility Across Applications | Axxon systems can handle a wide range of materials and applications, making them adaptable to various needs. |

4.1 Enhanced Product Quality

As an expert in the field, I’ve seen firsthand how Axxon dispensing solutions can significantly improve manufacturing processes. One of the standout benefits is the enhanced product quality achieved through precise dispensing. This accuracy ensures that materials like adhesives and encapsulants are applied uniformly, which is crucial for maintaining the integrity of semiconductor components. By reducing defects associated with uneven application, manufacturers can enhance the reliability and durability of their products.

4.2 Reducing Material Waste

Axxon systems excel in reducing material waste. The ability to dispense only the necessary amount of material not only cuts costs but also aligns with sustainability goals by minimizing excess consumption. This efficiency is especially important in industries where materials can be expensive or difficult to source. Overall, these benefits contribute to a more streamlined production process, allowing manufacturers to operate more effectively in a competitive market.

Claims Verification

| Claim | Factual Verification |

|---|---|

| Axxon dispensing solutions enhance product quality. | True: High precision in dispensing leads to uniform application and reduced defects. |

| Axxon systems reduce material waste during operation. | True: Precise control minimizes excess material usage, contributing to cost savings. |

5. Conclusion

Axxon dispensing solutions stand out due to their innovative technologies, precision engineering, and versatility across various applications in the semiconductor and electronics industries. Their advanced features, such as closed-loop linear motors and user-friendly interfaces, not only enhance production efficiency but also significantly improve product quality while minimizing waste. As an expert in the field, I have seen firsthand how these systems can transform manufacturing processes, enabling companies to stay competitive in a rapidly evolving market.

- 1.Axxon Mycronic Jetting Valves: The Future of Dispensing – This article delves into the mechanics and applications of Axxon Mycronic jetting valves, highlighting their advantages over traditional dispensing methods.

- 2.Axxon Mycronic Dispenser APJ1009 Overview – Learn about the key features and benefits of the APJ1009 dispenser, designed for precise adhesive dispensing and sealing applications.

- 3.Axxon Mycronic MYD50C Inline Dispensing System – Discover how the MYD50C addresses the challenges of semiconductor manufacturing with its high-speed and precise dispensing capabilities.