In SMT printing1, even the smallest components can have a big impact on production quality and efficiency. Among these, the squeegee blade often goes unnoticed despite its critical role in applying solder paste. Selecting the right squeegee blade type, material, and size is essential to achieving consistent, high-quality prints. But is your SMT squeegee blade affecting your print quality without you realizing it?

Yes, the choice of SMT squeegee blade has a direct impact on print quality. Using the right type, material, and size ensures uniform solder paste application, enhances accuracy, and prevents costly defects and rework in the manufacturing process.

So, how do you choose the best SMT squeegee blade for your needs? This guide breaks down the essentials, from material options to maintenance tips, to help you make an informed decision and achieve optimal results on your production line.

- True: The material the squeegee blade is made from can affect print quality. Metal blades are the most popular, but polyurethane blades can be used for single thickness or stepped stencils.

- False: All SMT squeegee blades work effectively with any SMT printing machine.

- True: Squeegee blade assembly is an element of the printing process that can have a significant effect on the print quality. We have seen that almost all of the above mentioned print qualities are affected by squeegee blade type and attack angle of the blade.

Table of Contents

- What Are the Different Types of SMT Squeegee Blades?

- Why Does Blade Material Matter?

- How Do Blade Length and Thickness Affect Printing?

- How Can I Properly Maintain My SMT Squeegee Blades?

What Are the Different Types of SMT Squeegee Blades?

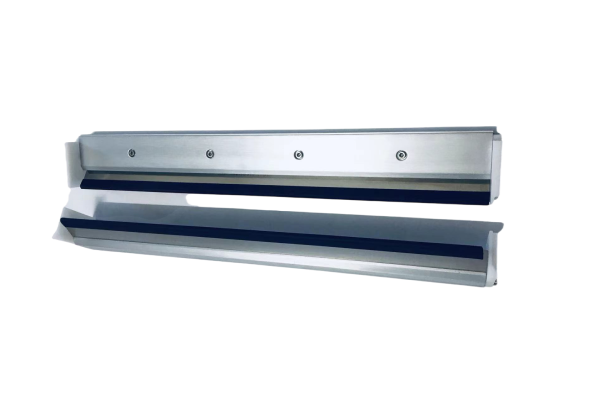

When it comes to SMT squeegee blades, not all options are created equal. The three primary types—metal, polyurethane, and hybrid—each offer unique benefits suited to different manufacturing needs. Let’s take a closer look at each type to see which one might be best for your application.

SMT squeegee blades come in three main types: metal, polyurethane, and hybrid. Metal blades provide precision and durability, polyurethane blades offer flexibility for delicate surfaces, and hybrid blades combine the best qualities of both for versatile applications.

Here is a quick rundown:

| Type | Description |

|---|---|

| Metal Blades | Ideal for high-precision applications; these blades are durable but may damage delicate substrates if not handled carefully. |

| Polyurethane Blades | Softer and more flexible, polyurethane blades are suitable for sensitive materials but wear out more quickly than metal. |

| Hybrid Blades | Combines metal’s precision with polyurethane’s flexibility; versatile and adaptable to varied production needs. |

Metal blades are often the top choice for high-precision SMT applications due to their durability and rigidity. Made from stainless steel or similar alloys, these blades ensure consistent paste deposition, especially on densely populated PCB designs where even slight misalignment can lead to costly production errors. However, metal blades can be unforgiving with delicate substrates, requiring careful handling to avoid damage during use.

Polyurethane blades, in contrast, offer a softer and more flexible alternative that reduces the risk of substrate damage. Ideal for applications involving sensitive materials, polyurethane blades conform more readily to stencil surfaces and are less likely to cause scratching. However, they tend to wear out more quickly than metal blades, meaning they might need frequent replacement in high-volume production.

Hybrid blades combine the rigidity of metal with the flexibility of polyurethane, providing a balanced solution for varied production environments. While they don’t reach the same precision as metal, hybrid blades excel in general-purpose applications where both flexibility and durability are needed. They are versatile enough for medium-complexity designs, helping to reduce print inconsistencies and improve production yields across a range of SMT processes.

- True: There are two squeegee material types: rubber/polyurethane squeegees and metal squeegees. Metal squeegees blades are most commonly used and operate at lower pressure than rubber variants.

- False: Polyurethane blades are equally durable as metal blades.

- True: There are different types of squeegee blades for SMT, including metal and polyurethane, single-thickness and mobile edge, and prototype.

Why Does Blade Material Matter?

The material of your SMT squeegee blade affects its longevity, flexibility, and overall effectiveness in solder paste application. From durable metals to softer polymers, each material offers distinct advantages and drawbacks in the production process.

The material of an SMT squeegee blade directly influences print quality, durability, and flexibility. Metal blades offer high precision, polyurethane blades are flexible and gentle on sensitive substrates, and hybrid blades balance the strengths of both for varied production needs.

Here is how SMT squeegee blade compares to material:

| Material | Description |

|---|---|

| Metal | Provides durability and precision, ideal for high-accuracy applications but may cause damage to sensitive substrates. |

| Polyurethane | Offers flexibility and gentleness on delicate surfaces, suitable for low-to-medium volume production but less durable. |

| Hybrid | Balances rigidity and flexibility, suitable for varied applications, though not as precise as pure metal blades. |

Metal blades, typically made from stainless steel, are favored for their durability and accuracy. They allow for fine control over solder paste application, which is especially important in high-density PCB designs where precision is critical. The rigidity of metal blades prevents excess paste from spreading, helping to maintain clear lines and reduce the risk of soldering errors. However, due to their hardness, metal blades require careful handling, particularly when working with sensitive substrates.

In contrast, polyurethane blades offer a softer alternative that conforms more easily to stencil surfaces. This flexibility is beneficial for applications involving delicate components that could be damaged by harder metals. While polyurethane blades wear down faster than their metal counterparts, they are often more affordable and provide sufficient durability for lower-volume or sensitive production needs.

Hybrid blades offer a middle ground, combining metal’s rigidity with polyurethane’s flexibility. Their dual-material structure enables them to deliver consistent solder paste deposits while adapting to different substrate surfaces, making them suitable for general-purpose SMT applications. Though they may not achieve the ultra-precision of metal, hybrid blades excel in providing balanced performance in diverse manufacturing environments.

- True: Metal blades are known for their high precision and durability.

- False: Polyurethane blades offer the same lifespan as metal blades.

- True: Blade material matters because it directly affects a blade’s sharpness, edge retention, corrosion resistance, durability, and overall performance depending on the intended use, with different materials offering varying levels of these qualities – for example, carbon steel is known for its excellent edge retention but can rust easily, while stainless steel is more corrosion resistant but may not hold an edge as well.

How Do Blade Length and Thickness Affect Printing?

The dimensions of an SMT squeegee blade—length and thickness—can significantly influence print quality and consistency. Choosing the right combination of these factors helps control solder paste volume and improves print stability, especially on intricate PCB designs.

Blade length and thickness impact paste consistency and print quality. Longer blades provide better coverage, while thicker blades offer greater precision. The right combination of length and thickness ensures optimal performance, especially for fine-pitch or complex PCB designs.

Here is a comparison:

| Dimension | Description |

|---|---|

| Length | Longer blades cover more surface area, offering better paste coverage but may introduce more flexing. |

| Thickness | Thicker blades provide better control and precision, ensuring consistent paste deposition but may be less flexible. |

| Combination | A balanced length and thickness are needed to maximize performance based on the specific needs of the PCB layout. |

SMT squeegee blades length determines how much of the stencil surface can be covered in one pass. Longer blades are more efficient for large-format stencils, as they reduce the number of passes needed and can improve production speed. However, longer blades may be prone to flexing, which can impact paste volume control on densely populated boards. For high-precision applications, shorter blades offer better stability, allowing for precise control of paste deposits on intricate designs.

Thickness, on the other hand, affects the blade’s rigidity and ability to apply consistent pressure across the stencil surface. Thicker blades provide stability, making them ideal for applications that require a uniform solder paste layer. However, the rigidity of thicker blades can make them less adaptable to stencil surface variations, potentially affecting paste uniformity. Thinner blades, though less rigid, offer more flexibility, allowing for even paste application on uneven surfaces.

Ultimately, the best combination of length and thickness depends on the specific demands of your project. In high-density or intricate designs, shorter, thicker blades often yield the best results. For general applications, a longer, thinner blade can help cover larger areas efficiently, offering a balanced approach between precision and speed.

- True: In printing, particularly in processes like flexography and gravure, the length and thickness of a doctor blade significantly impact the ink transfer, affecting the final print quality by controlling the amount of ink deposited on the printing surface; a longer and thinner blade generally allows for more precise ink control, while a shorter and thicker blade may be more durable but less precise in ink distribution.

- False: Thicker blades are always better for every application.

- True: To properly maintain your SMT squeegee blades, clean them thoroughly after each use, regularly inspect for wear and damage, rotate the blade to different edges to extend its lifespan, store them in a clean, dry environment, and replace them when signs of significant wear like nicks, uneven edges, or reduced printing quality appear; always follow the manufacturer’s specific guidelines for your squeegee blade type.

How Can I Properly Maintain My SMT Squeegee Blades?

Proper maintenance of SMT squeegee blades is essential to prolonging their lifespan and maintaining print quality. Cleaning, timely replacements, and correct storage all contribute to efficient production and fewer print defects.

Proper maintenance of SMT squeegee blades involves regular cleaning to remove paste buildup, routine inspections for wear, and storing blades in a controlled environment. These practices ensure consistent print quality and extend the lifespan of the blades.

Here are a few suggestions:

| Maintenance Task | Description |

|---|---|

| Cleaning | Regular cleaning prevents paste buildup, ensuring consistent performance and preventing contamination during printing. |

| Inspection | Routine inspections help identify wear and tear, allowing for timely replacement before poor print quality occurs. |

| Storage | Proper storage in a controlled environment protects blades from damage, warping, or contamination between uses. |

Cleaning is the most basic yet crucial maintenance step for SMT squeegee blades. After each production cycle, it’s essential to remove any residual solder paste to prevent buildup, which can compromise future prints. Using suitable cleaning solutions designed for SMT tools ensures that the blades stay free from residue without causing wear or corrosion.

Timely replacement is equally important. Even the best blades will wear down with repeated use, leading to edge nicks or scratches that affect paste deposition. Regular inspections help catch these signs early, allowing for replacement before they impact print quality. A proactive approach to replacement reduces defects and downtime, keeping your production line efficient and cost-effective.

Storage conditions also play a vital role in blade maintenance. SMT squeegee blades should be kept in controlled environments, protected from extreme temperatures or humidity that could cause warping or rust. Using blade covers or dedicated storage cases can further prevent accidental damage, ensuring the blades remain in optimal condition for the next production run.

Conclusion

SMT squeegee blades play a crucial role in the accuracy and efficiency of solder paste application during PCB assembly. Understanding the different types of blades—metal, polyurethane, and hybrid—along with the factors like material, length, thickness, and proper maintenance, can significantly impact print quality and production efficiency. By selecting the right blade for specific applications, whether it’s for precision, flexibility, or versatility, manufacturers can minimize defects, reduce downtime, and achieve optimal results in high-density and fine-pitch soldering tasks.

Proper maintenance, including regular cleaning, inspection, and storage, ensures that these blades retain their effectiveness and durability over time. With consistent upkeep and the right choice of blade, manufacturers can maintain smooth and efficient production, avoiding costly mistakes caused by wear and improper handling.

Choosing the best SMT squeegee blade requires a thoughtful consideration of your specific production needs, board design, and operational priorities. With the right blade material and maintenance strategy, manufacturers can ensure that their solder paste printing processes remain efficient, accurate, and cost-effective, leading to higher-quality products and fewer production disruptions.

1. IPC – Association Connecting Electronics Industries

IPC Official Website

IPC is a global trade association for the electronics industry, providing resources and standards on electronics manufacturing, including SMT processes and squeegee blade usage.

2.SMT Solutions – Everything About Squeegee Blades

SMT Solutions

This site offers detailed information about different types of squeegee blades, their applications, and best practices for selection and maintenance.

3.Apex Electronics – Guide to SMT Printing Equipment

Apex Electronics

Apex offers in-depth guides on various SMT components, including squeegee blades and printers, helping you select the right tools for your production line.

4.Henkel – Solder Paste and Printing Techniques

Henkel Solder Paste Guide

Henkel provides valuable insights into solder paste applications and the role that SMT equipment and blades play in achieving consistent print quality.

5.Techspray – Soldering and Cleaning Resources

Techspray

Offers detailed resources on soldering, cleaning, and maintaining SMT equipment, including squeegee blades, to ensure the longevity and efficiency of your assembly processes.