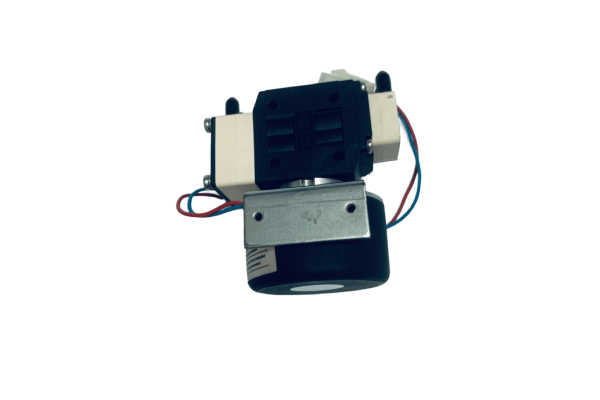

As a seasoned professional in the SMT manufacturing industry, I often find myself discussing the critical components that ensure the efficiency and reliability of our production processes. One such component is the solvent pump used in MPM printers. With models like 1016503, 1015076, and 2001589 at play 1, understanding their specifications and applications is crucial for anyone involved in SMT operations. In this article, I will provide a comprehensive overview of these solvent pumps, answering key questions and offering insights that can help you make informed decisions.

I’ve summarized the essential features of the three models of solvent pumps used in MPM printers. Each model serves a specific purpose within the SMT manufacturing process, primarily focusing on solvent dispensing for stencils cleaning.

| Model Number | Flow Rate (ML/MIN) | Compatibility | Typical Application |

|---|---|---|---|

| 1016503 | 300/400 | MPM Printer Momentum Series | stencils Cleaning |

| 1015076 | 200/300 | MPM Printer 125 | stencils Cleaning |

| 2001589 | 200/700 | MPM Printer Momentum II Series | stencils Cleaning |

Understanding the technical specifications of these solvent pumps is just the beginning. It’s crucial to delve deeper into how each model performs in real-world applications and what factors you should consider when selecting a pump for your specific needs.

Contents

- What Are the Key Features of Each Model?

- How Do I Choose the Right Solvent Pump?

- What Maintenance Practices Should I Follow?

- Where Can I Purchase These Pumps?

What Are the Key Features of Each Model?

When it comes to selecting a solvent pump for your MPM printer, knowing the key features of each model is essential. The models 1016503, 1015076, and 2001589 each have unique attributes that cater to different operational requirements.

Each model has been designed with specific operational parameters in mind, making them suitable for various applications within SMT processes.

| Feature | Model 1016503 | Model 1015076 | Model 2001589 |

|---|---|---|---|

| Flow Rate (ML/MIN) | 300/400 | 200/300 | 200/700 |

| Life | 10000H | 8000H | 8000H |

| Weight | 0.36KG | 0.34KG | 0.38kg |

| Size | 96*60*99mm | 96*59*98mm | 114*46*61mm |

| Applicable Medium | water and air | water and air | water and air |

The flow rate is a critical factor when selecting a solvent pump. For instance, Model 1016503 offers a flexible flow rate range of 300 to 400 ML/MIN, making it ideal for tasks requiring both precision and speed. This versatility can be particularly advantageous in environments where production demands fluctuate.Model 1015076 provides a flow rate of 200 to 300 ML/MIN, which may be more suitable for smaller scale operations or applications where lower solvent usage is desired.

In contrast, Model 2001589 boasts an impressive flow rate range of 200 to 700 ML/MIN, making it perfect for high-volume cleaning tasks where efficiency is paramount.In addition to flow rates, power consumption plays a significant role in operational costs. Models with lower power consumption can lead to savings over time, making them more economical choices for long-term use.

How Do I Choose the Right Solvent Pump?

Choosing the right solvent pump involves evaluating several factors beyond just specifications. It’s essential to consider compatibility with your existing equipment, the nature of your operations, and your specific cleaning requirements.

Compatibility with existing MPM printers is paramount; using a pump that fits seamlessly into your current setup will minimize downtime and ensure smooth operations.

| Consideration | Importance Level |

|---|---|

| Compatibility | High |

| Flow Rate | Medium |

| Power Efficiency | Medium |

| Cost | High |

When assessing compatibility, I always recommend consulting manufacturer guidelines or technical support to confirm that the chosen pump model works well with your specific printer version. Additionally, consider your production volume; if you frequently handle large batches or complex PCBs, opting for a higher flow rate may be advantageous.Cost is another significant factor; while it may be tempting to choose the least expensive option available, investing in a reliable pump can lead to long-term savings through reduced maintenance needs and enhanced performance.

What Maintenance Practices Should I Follow?

Proper maintenance of solvent pumps is crucial for ensuring their longevity and efficiency. Regular upkeep can prevent costly breakdowns and ensure consistent performance throughout their operational life.

Establishing a routine maintenance schedule can help identify potential issues before they escalate into significant problems.

| Maintenance Task | Frequency |

|---|---|

| Inspect Seals | Monthly |

| Clean Filters | Bi-Weekly |

| Check Flow Rate | Quarterly |

| Lubricate Moving Parts | Annually |

One essential maintenance task I emphasize is inspecting seals regularly. Worn or damaged seals can lead to leaks and decreased efficiency. Similarly, cleaning filters bi-weekly ensures that no debris obstructs the flow of solvents, which could impact performance.Monitoring flow rates quarterly allows you to detect any irregularities early on. If you notice a drop in flow rate compared to previous measurements, it may indicate wear or blockage within the system that requires immediate attention.

Where Can I Purchase These Pumps?

Finding reliable sources for purchasing SMT machine MPM printer solvent pumps is crucial for maintaining operational efficiency. Knowing where to look can save time and ensure you get quality products.

Purchasing directly from manufacturers ensures authenticity but may come at a premium price. Authorized dealers often provide support but might have limited stock availability.

| Source Type | Pros | Cons |

|---|---|---|

| Manufacturer Direct | Authenticity Guaranteed | Potentially Higher Prices |

| Authorized Dealers | Support Available | Limited Stock |

| Online Retailers | Competitive Pricing | Varying Quality |

Online retailers can offer competitive pricing but require careful consideration regarding product quality and seller reputation. Reading reviews and verifying seller credentials can help mitigate risks associated with online purchases.Additionally, consider reaching out to industry forums or professional networks where peers may recommend trusted suppliers based on their experiences.

Conclusion

In conclusion, understanding SMT machine MPM printer solvent pumps—specifically models like 1016503, 1015076 and 2001589—can significantly impact your operational efficiency in SMT manufacturing. By considering key features, evaluating compatibility and maintenance practices, and knowing where to purchase these pumps, you can make informed decisions that enhance productivity and reduce downtime.

As you navigate through your options for solvent pumps, what additional questions do you have about optimizing your SMT processes?

1.MPM Printer Maintenance and Troubleshooting Guides

- MPM Printer Support & Maintenance

This link provides detailed support documents and maintenance guides for MPM printers, including troubleshooting advice for motors and solvent pumps.

2.Authorized MPM Printer Parts Suppliers

- SMT Equipment and Parts Suppliers

A trusted marketplace for SMT equipment and replacement parts, including motors and solvent pumps for MPM printers. Users can check availability, pricing, and reliability of parts.

3.Solvent Pump Maintenance Best Practices

- Solvent Pump Care and Maintenance

A resource dedicated to maintaining solvent pumps, with detailed instructions for cleaning, repairing, and ensuring the longevity of pumps in industrial applications.

4.SMT Equipment Supplier Reviews

- SMT Equipment Supplier Reviews

User reviews and ratings of various SMT equipment suppliers, including feedback on motor and solvent pump models. This will help users find trusted sources for parts and services.

5.Troubleshooting MPM Printer Motors and Pumps

- MPM Printer Motor Troubleshooting

A dedicated troubleshooting resource for MPM printer motors, including how to diagnose and fix common issues with the motors and pumps.