Introduction

As an expert in the field of Surface Mount Technology (SMT), I understand that the performance of MPM printers heavily relies on the precision and quality of their components. Among these, SMT squeegee blades play a crucial role in ensuring optimal printing results. In this article, I will provide an in-depth look at SMT squeegee blades, their types, materials, sizing, and the best suppliers in the market. My goal is to equip you with the knowledge necessary to make informed decisions regarding squeegee blades for MPM Momentum II BTB Stencil Printer 1.

Types of Squeegee Blades Compatible with MPM Printers

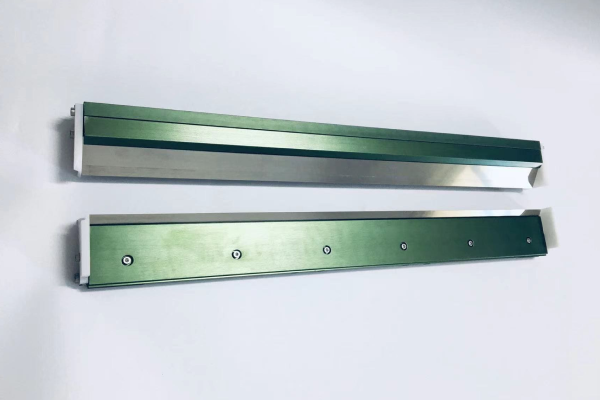

Overview of Squeegee Blades

SMT Squeegee blades are essential components in SMT printing, primarily used to apply solder paste onto printed circuit boards (PCBs). Their function is to ensure even distribution of solder paste across the stencil, which directly impacts the quality and reliability of the printed circuit assembly.

Material Types

The choice of material for SMT squeegee blades significantly affects their performance and longevity. Here are the main types:Rubber Squeegee Blades

Rubber blades are known for their flexibility and ability to conform to surface irregularities. They are ideal for applications requiring gentle handling of solder paste, particularly in fine-pitch printing. The benefits include:

- Characteristics: High elasticity and good wear resistance.

- Benefits: Reduced risk of damage to delicate components and better paste release.

- Ideal Applications: Fine pitch and small component placements.

Steel Squeegee Blades

Steel blades offer durability and precision. They are less flexible than rubber but provide excellent control over paste deposition. Key points include:

- Characteristics: Rigid structure with a sharp edge.

- Benefits: Long lifespan and consistent performance under high-speed printing.

- Ideal Applications: General-purpose printing where high accuracy is required.

Composite Materials

Composite SMT squeegee blades combine materials to leverage the benefits of both rubber and steel. They offer a balance between flexibility and durability:

- Characteristics: Hybrid construction that enhances performance.

- Benefits: Versatile use across various applications.

- Ideal Applications: Situations where both flexibility and precision are needed.

Size Specifications

Selecting the right size of SMT squeegee blade is critical for optimal performance. Common sizes available for MPM printers include:

- 150mm

- 220mm

- 300mm

- 360mm

- 430mm

- 520mm

- 608mm

Choosing the correct size ensures proper contact with the stencil and effective paste transfer, which is vital for achieving high-quality prints.

Supplier Comparison

Leading Suppliers of Squeegee Blades

When it comes to sourcing SMT squeegee blades, two trusted vendors stand out in the market.

Supplier A: Transition Automation, Inc.

- Price Range: Competitive pricing based on blade type and material.

- Availability: Wide range of products including custom sizes.

- Shipping Options: Fast shipping with options for bulk orders.

Supplier B: SMTCOMPONENTS CO., LIMITED

- Price Range: Affordable options with discounts on larger quantities.

- Availability: Specializes in MPM Momentum II 100 Stencil Printer series blades.

- Shipping Options: Reliable shipping services with tracking options.

How to Choose a Supplier

When selecting a supplier for SMT squeegee blades, consider the following factors:

- Pricing: Compare prices across suppliers to find competitive rates.

- Quality: Look for suppliers that guarantee high-quality materials and craftsmanship.

- Customer Service: Evaluate responsiveness and support offered by the supplier.

Performance Insights

Reviews and Testimonials

User feedback is invaluable when assessing different blade types. I have compiled insights from various users:

- Rubber Blades: Users report excellent paste release and minimal wear over time, making them ideal for fine-pitch applications.

- Steel Blades: Customers appreciate their durability and consistent performance, especially in high-speed operations.

Case Studies

To illustrate real-world applications, here are two case studies:

- Case Study 1 – Hon Hai Precision Industry Co., Ltd. Experience with Rubber Blades

Company A switched to rubber squeegee blades for their fine-pitch printing needs. They noted a significant improvement in paste transfer efficiency and reduced defects in assembly. - Case Study 2 – BYD Company Limited Experience with Steel Blades

Company B opted for steel blades during their transition to higher-speed production lines. They reported enhanced accuracy in paste application, leading to fewer reworks.

Common Performance Issues

Despite their effectiveness, users may encounter some common performance issues:

- SMT Squeegee Blade Wear

- Causes: Prolonged use without replacement can lead to wear.

- Effects: Deterioration affects print quality; uneven paste application may occur.

- Solutions: Regularly inspect blades and replace them as needed.

- Inconsistent Printing Results

- Causes: Incorrect blade size or material choice can lead to poor performance.

- Effects: Variability in print quality can result in assembly defects.

- Solutions: Ensure proper blade selection based on application requirements.

Addressing Specific Production Challenges

To optimize performance in your SMT production line, consider these tips:

- Regularly maintain your printer and squeegee system to prevent buildup of solder paste residue.

- Train operators on proper blade handling techniques to extend blade life.

- Monitor production metrics closely to identify any deviations early.

Conclusion

In summary, selecting the right squeegee blade for MPM Printer is crucial for achieving high-quality prints and maintaining efficient production processes. By understanding the various types of blades available—rubber, steel, and composite—as well as their specifications and supplier options, you can make informed decisions that enhance your printing operations. Remember that regular maintenance and proper training are key factors in optimizing performance. With this knowledge at hand, you can confidently navigate the complexities of SMT printing technology.