Overview of Axxon Mycronic Jetting Valves

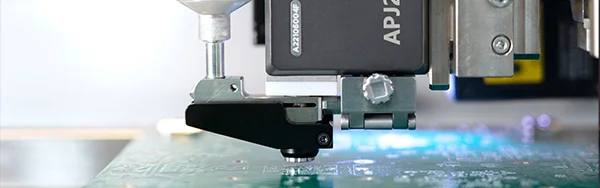

Axxon Mycronic jetting valves, particularly the APJ1500 model, represent a significant advancement in dispensing technology, particularly for applications requiring high precision and speed. These valves utilize piezoelectric actuation to achieve rapid and accurate fluid dispensing, making them suitable for a wide range of materials, including adhesives, solder pastes, and coatings. Key features include:

- High-speed jetting capability: The APJ1500 can dispense up to 1,000 dots per second, which is three to seven times faster than traditional methods.

- Non-contact dispensing: This feature allows for precise material placement without physical contact with sensitive components, making it ideal for densely packed assemblies.

- Adjustable droplet size: The valves can dispense droplets as small as 0.2 mm in diameter, with capabilities for even smaller sizes depending on the application.

- Temperature control: Some models include mechanisms to regulate temperature, crucial for maintaining material viscosity during dispensing.

These features make Axxon Mycronic jetting valves indispensable in modern manufacturing environments where speed, accuracy, and flexibility are paramount.

Importance in Modern Manufacturing

Axxon Mycronic jetting valves play a critical role in various industries, including electronics, automotive, and medical device manufacturing. Their importance can be summarized as follows:

- Enhanced Efficiency: The high-speed operation and minimal waste associated with these valves significantly increase production throughput. This is particularly vital in fast-paced sectors like electronics manufacturing, where time-to-market is crucial.

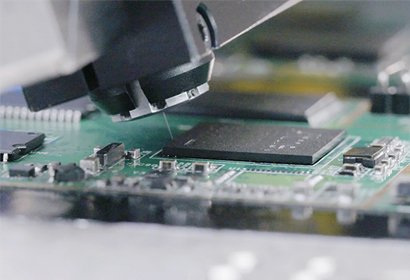

- Precision and Reliability: The ability to dispense materials accurately ensures the integrity of products. For instance, in semiconductor packaging, precise underfill applications enhance reliability by filling gaps between chips and substrates.

- Versatility Across Applications: These valves are adaptable to various manufacturing processes such as underfilling, dam and fill techniques, and precision coating. Their capability to handle a wide range of fluid viscosities further extends their applicability across different industries.

- Support for Advanced Manufacturing Technologies: As industries embrace advanced manufacturing techniques like automation and smart factories, the role of high-performance dispensing solutions like Axxon Mycronic jetting valves becomes increasingly vital. They enable manufacturers to meet the growing demands for complex assemblies with high precision.

In summary, Axxon Mycronic jetting valves are essential tools in modern manufacturing that enhance productivity while ensuring quality and precision across various applications. Their innovative design and functionality position them as key components in the future of manufacturing technology.

Understanding Axxon Mycronic Jetting Valves

Axxon Mycronic jetting valves are advanced dispensing solutions designed for high precision and efficiency in various manufacturing applications. This overview delves into their key features and specifications, focusing on their design and technology, viscosity handling capabilities, and flow rate precision.

Axxon Mycronic Jetting Valves: Key Features and Specifications

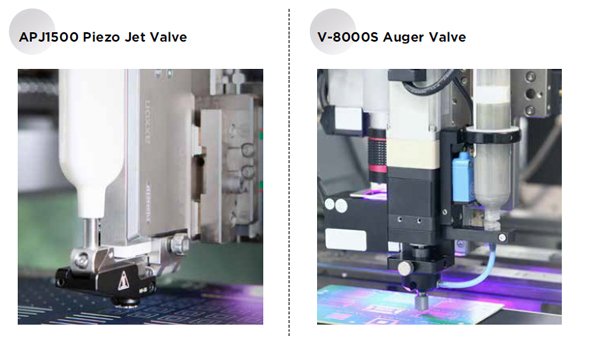

Axxon Mycronic jetting valves, particularly the APJ1500 and APJ2000 models, are designed for high-performance dispensing in various manufacturing applications. Their advanced technology and features make them essential tools in industries such as electronics, automotive, and medical devices.

Design and Technology

- Piezoelectric Actuation: Both the APJ1500 and APJ2000 utilize piezoelectric technology, enabling rapid and precise dispensing of materials. This mechanism allows for high-speed operation without the need for Z-axis movement, achieving jetting speeds of up to 1,000 dots per second.

- Unique Structural Design: The valves feature a strong jetting force generated within a short stroke, which minimizes bubbles and splashes during dispensing. This design enhances the integrity of the materials applied.

- Temperature Control: Integrated temperature control mechanisms for both the valve body and fluid channel ensure consistent material viscosity, critical for optimal dispensing performance.

Viscosity Handling Capabilities

Axxon Mycronic jetting valves are capable of handling a wide range of fluid viscosities:

- Viscosity Range: The APJ1500 can accommodate fluids with viscosities from 1 to 200,000 cps, making it suitable for various applications from low-viscosity liquids to highly viscous adhesives.

- Versatility: This capability allows the valves to be used across different sectors, including semiconductor packaging (underfill), automotive adhesive applications, and precision coating tasks.

Flow Rate Precision

Precision in flow rates is a significant feature of Axxon Mycronic jetting valves:

- Minimum Dot Diameter: The valves can dispense droplets as small as 0.2 mm, with capabilities to achieve even smaller sizes (down to 0.14 mm) for specific materials. This precision is crucial for applications requiring fine detail.

- High Frequency Operation: The valves operate at frequencies up to 1,000 Hz, allowing for rapid dispensing cycles that significantly increase throughput compared to traditional methods.

- Consistent Volume Control: The design ensures that each droplet dispensed meets exact specifications, minimizing waste and enhancing quality control.

Specifications Summary

| Technical Data | APJ1500 | APJ2000 |

|---|---|---|

| Maximum Frequency | 0~1000 Hz | Up to 550 Hz |

| Maximum Fluid Pressure | 0~0.3 MPa | Not specified |

| Minimum Dot Diameter | 0.2 mm (down to 0.14 mm) | 0.165 mm |

| Applicable Fluid Viscosity | 1~200,000 cps | Up to 200,000 cps |

| Dimensions | 117 × 25.4 × 76 mm | Not specified |

| Weight | 440 g | Not specified |

| Maximum Nozzle Heating Temperature | 200 °C | Not specified |

Axxon Mycronic jetting valves are engineered for excellence in precision dispensing applications. Their advanced design features, broad viscosity handling capabilities, and precise flow rate control make them invaluable in modern manufacturing processes. As industries continue to demand higher efficiency and accuracy, these valves stand out as critical components in achieving those goals.

Axxon Mycronic Jetting Valves: Suppliers and Pricing

When considering the purchase of Axxon Mycronic jetting valves, it is important to identify reliable suppliers and understand the pricing landscape. This overview provides insights into potential suppliers and an overview of pricing, including factors influencing costs and comparisons across different vendors.

Identifying Axxon Mycronic Jetting Valve Suppliers

Axxon Mycronic jetting valves are available from various suppliers, including direct manufacturers and distributors. Key suppliers include:

- Axxon – Mycronic: The official manufacturer, Axxon provides comprehensive support and a range of dispensing solutions tailored to various industries. Their facilities are located in Shenzhen, China, with support teams across the globe, including the USA and Europe.

- SMTCOMPONENTS CO., LIMITED: This supplier offers a variety of dispensing solutions, including Axxon Mycronic jetting valves. They focus on high precision applications in electronics manufacturing.

- Local Distributors: Depending on your region, there may be local distributors that specialize in industrial automation and dispensing technologies, providing additional options for procurement.

Pricing Overview

The pricing for Axxon Mycronic jetting valves varies based on model specifications and supplier offerings. Generally, the prices range from $11,000 to $32,000 per unit, depending on features such as jetting speed, viscosity handling capabilities, and additional functionalities.

Factors Influencing Pricing

Several factors can affect the pricing of Axxon Mycronic jetting valves:

- Model Specifications: Higher-end models with advanced features (e.g., APJ2000) tend to be more expensive due to their enhanced capabilities for handling high-viscosity fluids and higher jetting forces.

- Supplier Location: Shipping costs and import duties can influence final prices, especially if purchasing from international suppliers.

- Volume Discounts: Many suppliers offer discounts for bulk purchases or long-term contracts, which can significantly reduce the unit price.

- Customization Options: Custom configurations or additional features may increase the base price of the valves.

Cost Comparison Across Suppliers

A preliminary comparison of prices from different sources indicates variability based on model and supplier:

| Supplier | Model | Price Range | Notes |

|---|---|---|---|

| Local Distributors | APJ1500/APJ2000 | $12,000 – $33,000 | Official manufacturer pricing |

| Axxon – Mycronic | APJ1500/APJ2000 | $11,000 – $32,000 | Official manufacturer pricing |

| SMTCOMPONENTS CO., LIMITED | Various Models | Varies | Focus on precision dispensing solutions |

Purchasing Axxon Mycronic jetting valves involves identifying reputable suppliers and understanding the pricing dynamics influenced by model specifications and market factors. By exploring options from both direct manufacturers and distributors, buyers can find competitive prices that meet their operational needs while ensuring high-quality dispensing solutions for their manufacturing processes.

Axxon Mycronic Jetting Valves: Handling Requirements

Axxon Mycronic jetting valves, such as the APJ1500 and APJ2000, are designed to meet the demanding requirements of modern manufacturing processes. Their capabilities in viscosity management, compatibility with automated systems, and integration with existing production lines make them essential tools for precision dispensing applications.

Specific Viscosity Management

Axxon Mycronic jetting valves excel in managing a wide range of fluid viscosities, which is crucial for various applications:

- Viscosity Range: The APJ1500 can handle fluids with viscosities from 1 to 200,000 cps, making it suitable for both low-viscosity liquids and highly viscous materials. This flexibility allows manufacturers to use these valves across different sectors, including electronics, automotive, and medical devices.

- Temperature Control: Both models incorporate temperature control mechanisms that help maintain consistent material viscosity during dispensing. This is particularly important as fluctuations in temperature can affect the performance and accuracy of dispensing operations.

- Non-Contact Dispensing: The design allows for precise material placement without physical contact with sensitive components, reducing the risk of contamination and damage while accommodating various viscosity levels.

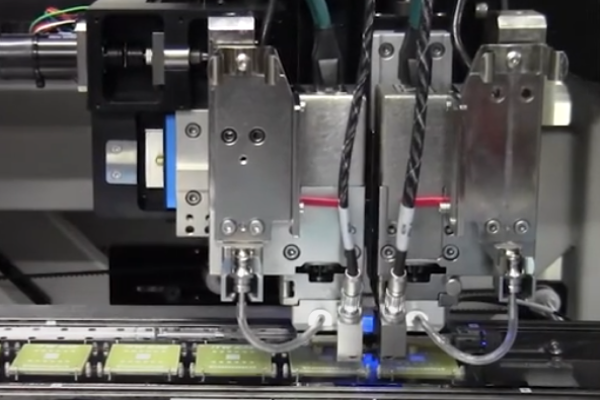

Compatibility with Automated Systems

Axxon Mycronic jetting valves are engineered for seamless integration into automated manufacturing systems:

- Controller Compatibility: These valves are compatible with various automation controllers, allowing easy integration into existing production lines. This flexibility supports the growing trend toward automation in manufacturing processes.

- Modular Design: The modular structure of the valves facilitates quick maintenance and reduces downtime, ensuring that they can be easily serviced without disrupting production schedules. This design is crucial for maintaining efficiency in high-volume manufacturing environments.

- Adjustable Parameters: Users can adjust droplet size, jetting speed, and frequency settings to tailor the dispensing process to specific application needs. This adaptability enhances their usability within automated systems where precision is paramount.

Integration with Existing Production Lines

Integrating Axxon Mycronic jetting valves into existing production lines involves several considerations:

- Ease of Installation: The valves are designed to be easily installed within existing setups, minimizing the need for extensive modifications. Their compatibility with standard interfaces makes them suitable for a wide range of equipment.

- Enhanced Throughput: With jetting speeds up to 1,000 dots per second, these valves significantly enhance production throughput compared to traditional dispensing methods. This capability is essential for manufacturers looking to increase efficiency without compromising quality.

- Application Versatility: The ability to dispense a variety of materials—such as adhesives, solder pastes, and coatings—makes these valves versatile tools that can adapt to different production needs. This versatility is particularly valuable in industries where product specifications frequently change.

Axxon Mycronic jetting valves are equipped to handle specific viscosity management challenges while being compatible with automated systems and easily integrated into existing production lines. Their advanced features ensure high precision and efficiency in dispensing applications across multiple industries. As manufacturing processes continue to evolve, these valves will play a crucial role in meeting the demands for accuracy and reliability in fluid dispensing solutions.

Challenges in Axxon Mycronic Jetting Valves Applications

Axxon Mycronic jetting valves, specifically models like the APJ1500 and APJ2000, are designed to enhance precision dispensing in various manufacturing processes. However, their applications come with specific challenges that manufacturers must navigate to maximize efficiency and product quality.

High-Speed, Non-Contact Dispensing

While high-speed, non-contact dispensing is a significant advantage of Axxon Mycronic jetting valves, it also presents challenges:

- Precision Maintenance: Achieving high-speed dispensing without compromising accuracy can be difficult. Variability in droplet size and placement can lead to defects, especially in intricate designs requiring tight tolerances. The closed-loop control system in the APJ1500 helps mitigate this by adjusting dispensing weight in real-time, but consistent calibration is essential to maintain performance under varying conditions .

- Material Behavior: Different materials respond differently under high-speed conditions. For instance, highly viscous materials may not jet as effectively at high speeds, leading to potential application issues. Manufacturers must ensure that the selected materials are compatible with high-speed dispensing technologies to avoid performance degradation.

Reducing Waste and Production Errors

Minimizing waste and production errors is a critical goal for manufacturers using Axxon Mycronic jetting valves, but several challenges can hinder this objective:

- Calibration and Setup: The need for precise calibration of the dispensing system is paramount. Any discrepancies can lead to uneven application, resulting in defects that increase waste. The advanced equipment calibration compensation technology in the APJ1500 addresses this challenge by compensating for variations due to equipment or environmental changes .

- Monitoring and Feedback: Continuous monitoring of the dispensing process is necessary to ensure that material is applied correctly. While the Au series dispensing software includes features for real-time feedback and adjustments, integrating these systems effectively into existing workflows can be complex and requires operator training.

Maintaining Accuracy and Efficiency

Ensuring both accuracy and efficiency during production processes using Axxon Mycronic jetting valves involves overcoming specific hurdles:

- Complexity of Integration: Integrating these advanced valves into existing production lines can be challenging. Compatibility with automated systems requires careful planning and potentially significant modifications to current setups. Ensuring that all components work seamlessly together is essential for maintaining efficiency without sacrificing accuracy.

- Training and Expertise: Operators need adequate training to manage the sophisticated controls and features of Axxon Mycronic jetting valves effectively. Without proper knowledge of the system capabilities and limitations, there is a risk of human error that could lead to production delays or increased waste .

- Environmental Factors: External factors such as temperature fluctuations and humidity can affect material viscosity and dispensing accuracy. Maintaining optimal environmental conditions is crucial but can be challenging in dynamic manufacturing environments.

While Axxon Mycronic jetting valves offer significant advantages in precision dispensing applications, manufacturers face several challenges related to high-speed operation, waste reduction, and maintaining accuracy. By addressing these challenges through careful calibration, effective training, and robust integration strategies, companies can fully leverage the capabilities of these advanced dispensing technologies to enhance their production processes.

Axxon Mycronic Jetting Valves: Solutions to Improve Production Efficiency

Axxon Mycronic jetting valves, such as the APJ1500 and APJ2000, are pivotal in enhancing production efficiency across various manufacturing sectors. By integrating advanced technology, implementing best practices, and examining successful case studies, manufacturers can leverage these valves to optimize their processes.

Advanced Technology Integration

The integration of advanced technologies in Axxon Mycronic jetting valves significantly contributes to improved production efficiency:

- High-Speed Jetting: The APJ1500 achieves jetting speeds of up to 1,000 dots per second, which is three to seven times faster than traditional dispensing methods. This capability allows for quicker production cycles and higher throughput in high-volume manufacturing environments.

- Non-Contact Dispensing: This feature minimizes the risk of damaging sensitive components during the dispensing process. It is particularly advantageous in applications with tight spaces, where traditional methods may struggle. The ability to dispense droplets as small as 1 nanoliter further enhances flexibility and precision.

- Advanced Control Systems: Axxon Mycronic valves incorporate intelligent control systems that enhance operational efficiency. These systems allow for real-time adjustments based on feedback, ensuring consistent quality and reducing waste during production.

Best Practices for Implementation

To maximize the benefits of Axxon Mycronic jetting valves, manufacturers should adopt the following best practices:

- Proper Calibration: Regular calibration of the dispensing system is essential to maintain accuracy and minimize waste. Implementing automated calibration routines can help ensure that the system operates within specified tolerances.

- Training Operators: Providing comprehensive training for operators on the features and capabilities of the jetting valves is crucial. Understanding how to adjust settings for different materials and applications can significantly impact production efficiency.

- Routine Maintenance: Establishing a routine maintenance schedule helps prevent downtime and ensures that the valves operate at peak performance. The modular design of Axxon Mycronic valves facilitates quick maintenance, reducing overall operational costs.

- Material Compatibility Testing: Before full-scale implementation, conducting tests with various materials can help identify optimal settings for viscosity handling and droplet size. This practice ensures that the dispensing process is tailored to specific production needs.

Case Studies of Successful Applications

Examining successful applications of Axxon Mycronic jetting valves provides valuable insights into their effectiveness in improving production efficiency:

- Micro LED Technology: In the electronics sector, the APJ1500 has been utilized for precise material dispensing in Micro LED manufacturing. Its high-speed capabilities and non-contact features have enabled manufacturers to achieve higher brightness levels while minimizing waste during assembly processes.

- Automotive Adhesive Dispensing: Axxon Mycronic valves have been successfully implemented in automotive manufacturing for adhesive bonding applications. The ability to dispense a variety of adhesives with high precision has led to improved product reliability and reduced material costs.

- Medical Device Manufacturing: In the life sciences sector, these jetting valves are used for dispensing biocompatible adhesives in medical devices. Their precision ensures patient safety while enhancing device reliability, showcasing how advanced dispensing technology can meet stringent industry standards.

Axxon Mycronic jetting valves offer innovative solutions to enhance production efficiency across various industries. By integrating advanced technologies, implementing best practices, and learning from successful case studies, manufacturers can optimize their dispensing processes. As industries continue to evolve, leveraging these advanced tools will be crucial for maintaining competitiveness and achieving operational excellence.

Conclusion

Summary of Key Considerations

Axxon Mycronic jetting valves are pivotal in enhancing manufacturing efficiency through advanced dispensing technology. Key considerations for their successful implementation include:

- Precision and Speed: The ability to dispense materials at high speeds (up to 1,000 dots per second) while maintaining accuracy is crucial for high-volume production environments. This capability significantly reduces cycle times and increases throughput.

- Material Versatility: Axxon Mycronic valves can handle a wide range of viscosities, accommodating various materials such as adhesives, solder pastes, and coatings. This adaptability is essential for manufacturers looking to optimize their processes across different applications.

- Integration with Automation: The compatibility of these valves with automated systems enhances operational efficiency. Their non-contact dispensing method minimizes the risk of damage to sensitive components, making them suitable for intricate assembly tasks.

- Training and Maintenance: Proper training for operators and routine maintenance of the dispensing systems are vital to ensure consistent performance and minimize downtime. Regular calibration and monitoring are necessary to maintain the precision of the dispensing process.

Future Trends in Jetting Technology

The future of jetting technology, particularly with Axxon Mycronic valves, is poised for significant advancements that will further enhance production capabilities:

- Increased Automation: As manufacturing processes become more automated, jetting valves will likely integrate with smart manufacturing systems. This integration will enable real-time monitoring and adjustments based on production data, leading to even greater efficiencies.

- Enhanced Material Compatibility: Ongoing research into new materials will expand the range of fluids that can be dispensed effectively. Innovations in material science could lead to better performance characteristics and broader applications in industries such as electronics and biomedical devices.

- Sustainability Focus: With growing emphasis on sustainability, future jetting technologies may incorporate eco-friendly materials and processes that reduce waste and energy consumption. Manufacturers will increasingly seek solutions that align with environmental goals while maintaining performance.

- Advanced Control Systems: The development of more sophisticated control algorithms will improve the precision and adaptability of jetting valves. These systems could enable finer adjustments in droplet size and dispensing speed based on real-time feedback from production lines.

In summary, Axxon Mycronic jetting valves represent a significant advancement in fluid dispensing technology within manufacturing processes. By focusing on precision, versatility, and integration with automation, these valves are set to play a crucial role in the future of efficient manufacturing. As trends evolve toward greater automation, enhanced material compatibility, sustainability, and advanced control systems, manufacturers can expect continued improvements in productivity and quality through the adoption of these innovative solutions.