Smart Factory Solutions are transforming the electronics manufacturing industry, addressing critical needs for cost reduction, increased production speed, and efficiency. Through automation, real-time data analysis, and interconnected systems, Smart Factories minimize human error, streamline operations, and boost productivity.

By integrating technologies like AI, IoT, and machine learning, these solutions allow manufacturers to predict and prevent bottlenecks, optimize resource usage, and achieve high precision in complex processes. This digital shift not only enhances scalability but also facilitates more responsive production lines that quickly adapt to changing market demands, ultimately giving companies a competitive edge in a fast-evolving industry.

Surface Mount Technology (SMT) machines are essential for responsive manufacturing, enabling precise, high-speed assembly of electronic components onto PCBs. By automating placement, soldering, and inspection processes, SMT printer machines boost production efficiency, reduce errors, and allow rapid adaptation to design changes, meeting fast-paced market demands effectively.

This guide provides an overview of Surface Mount Technology (SMT), focusing on SMT printer machines that apply solder paste to PCBs with precision. It explores various types and popular brands, such as Mpm printer, DEK, EKRA, Gkg, and Yamaha, while also highlighting companies recognized for manufacturing reliable and advanced SMT printing equipment.

What is Surface Mount Technology?

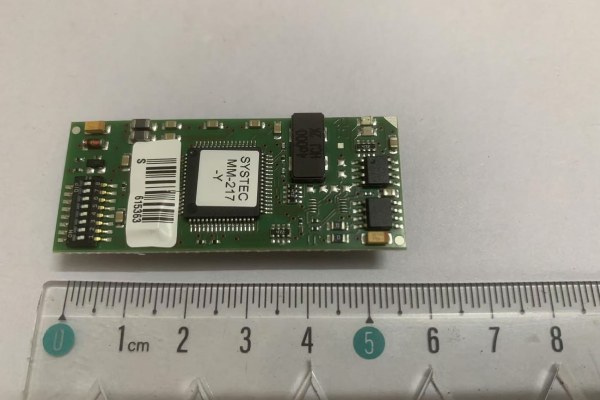

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), without the need for traditional wire leads. Components designed for SMT, known as surface-mount devices (SMDs), are smaller and lighter than through-hole counterparts, allowing for more compact and efficient circuit designs.

SMT enhances manufacturing automation by enabling faster, more precise component placement, reducing production costs, and minimizing manual labor. This technology also improves electrical performance, as shorter leads reduce inductance and resistance, resulting in faster signal transmission. SMT is commonly used in modern electronics, including smartphones, computers, and automotive control systems, where miniaturization and reliability are crucial.

The SMT process involves steps like solder paste application, component placement, and reflow soldering to secure components. With Moore’s law driving smaller component sizes, SMT has become essential in achieving advanced, high-density circuits.

What does SMT Printer Machine do?

An SMT printer machine applies solder paste onto the surface of printed circuit boards (PCBs) as the first step in Surface Mount Technology (SMT) assembly. This solder paste acts as an adhesive to hold electronic components in place before soldering. The machine precisely deposits solder paste onto designated pads on the PCB using a stencil and squeegee mechanism, ensuring accuracy and consistency for each board.

High-quality printing is essential for strong component bonding and reliable electrical connections. SMT printers are crucial for high-speed, automated PCB assembly lines, where precision and repeatability significantly impact product quality and yield.

Types of SMT Printer Machines

The success rate of Surface Mount Technology (SMT) assembly largely relies on the quality and precision of inputs from various machines, such as SMT printers, pick-and-place machines, and reflow ovens. Accurate solder paste application, precise component placement, and controlled soldering are essential for reliable and efficient PCB assembly.

In Surface Mount Technology (SMT), printers play a crucial role in applying solder paste onto PCB pads, an essential step in ensuring components securely adhere to the board during assembly. Leading SMT printers include DEK Horizon, renowned for precision and high-speed printing, making it a popular choice for large-scale production.

Another favorite, the Ekra X5, is known for its adaptability and accurate stencil alignment, accommodating various board sizes and materials. Speedline MPM printers, such as the Momentum Series, are lauded for advanced vision systems that improve accuracy and quality, essential for high-yield production. These printers streamline solder paste deposition, enhancing adhesion and reliability for tiny components. The Yamaha YSP10, with its automatic stencil replacement and monitoring features, also stands out in environments needing quick changeovers.

Together, these SMT printers meet modern manufacturing demands, advancing production efficiency and quality in the electronics industry.

Manual SMT Printer Machines

Manual SMT printers are essential tools for smaller-scale electronics production, prototyping, or environments where automated machines may not be viable. Unlike their automated counterparts, manual SMT printers require the operator to align and control the stencil and PCB, which demands precision and skill.

Popular models include the HCT MT-350 and Neoden PM3040, both valued for their ease of use and reliable stencil alignment for accurate solder paste application. These printers allow users to control printing pressure and speed, which can be adjusted to suit various PCB designs.

Manual SMT printers typically involve a frame to hold the stencil securely over the PCB, with handles or levers for controlled paste application. Despite requiring more hands-on operation, manual SMT printers offer flexibility and affordability, making them ideal for small businesses, labs, and educational institutions focused on SMT training and low-volume production.

Semi-Automatic SMT Printer Machines

Semi-automatic SMT printers bridge the gap between fully manual and automated printing, offering a balanced solution for small to mid-scale production environments.

These machines, such as the Neoden FP2636 and HCT MT-500, combine manual stencil alignment with motorized printing mechanisms, enhancing precision and consistency without the full automation cost. Operators manually position the PCB and stencil, but the printer controls the squeegee’s movement, pressure, and speed for accurate solder paste application. This hybrid approach reduces human error, ensuring a higher-quality print while maintaining flexibility for different PCB sizes and designs.

Semi-automatic printers often feature user-friendly control panels, enabling quick adjustments and faster setup times than manual machines. Ideal for prototyping, short-run production, and educational purposes, semi-automatic SMT printers increase throughput and yield by improving paste deposition uniformity, making them a valuable addition to any electronics manufacturing or assembly setup focused on efficiency and quality.

Automatic SMT Printer Machines

Automatic SMT printers are high-precision machines designed for large-scale, high-volume electronics production. These advanced systems, including models like the DEK NeoHorizon and MPM Momentum II BTB Stencil Printer, automate the entire printing process, from PCB alignment to paste application, using vision-based systems and robotic controls for maximum accuracy.

Equipped with features like auto-stencil cleaning, solder paste inspection, and dynamic pressure adjustments, automatic SMT printers ensure consistent and high-quality paste deposition across PCBs, even at rapid speeds. Their precision minimizes defects like misalignment or insufficient solder, critical for high-density components typical in modern electronics. With capabilities for rapid changeovers and minimal operator intervention, these printers are ideal for high-mix, high-volume environments where efficiency is paramount.

The investment in automatic SMT printers translates into faster production cycles, lower labor costs, and significantly reduced rework, making them essential for industries prioritizing quality and throughput, such as consumer electronics and automotive manufacturing.

The Best SMT Printer Machine Manufacturers

#1 MPM Printers

MPM Edison II ACT is a premier SMT printer that offers a comprehensive line solution tailored to meet diverse production needs. Known for its high precision and reliability, it supports optimal productivity in various environments, ensuring consistent, high-quality printing for efficient and scalable SMT assembly processes 1.

MPM Edison II ACT (Automated Changeover Technology) builds upon the robust MPM Edison platform, renowned as one of the industry’s most accurate and technologically advanced SMT printers. Engineered with a machine alignment capability of ±8 microns and wet print accuracy of ±15 microns (≥2 Cpk @ 6 sigma), the Edison II ACT achieves precise solder paste deposition. This high accuracy is vital for supporting the increasing miniaturization of components and densely populated boards typical in applications across the semiconductor, automotive, and smart device industries.

The printer’s impressive process capability, rated at over 2 Cpk for 0201 metric components, assures exceptional quality and consistency, meeting stringent industry requirements for compact and complex assemblies. Its advanced capabilities directly address the challenges of achieving tight tolerances and high yields when manufacturing tiny, high-density components. As such, the MPM Edison II ACT represents an ideal solution for industries that demand both precision and efficiency as board complexity continues to grow.

One of the standout features of the Edison II ACT is its patented Automated Changeover Technology (ACT), which revolutionizes production line changeovers. In traditional setups, changeovers are labor-intensive, time-consuming, and prone to errors, requiring skilled personnel to adjust fixtures, align stencils, and calibrate settings manually. The ACT system automates these steps, significantly reducing downtime while ensuring a seamless transition between different production runs. This automation minimizes the possibility of human error, boosts throughput, and cuts labor costs—important considerations in high-mix manufacturing environments where frequent product changes are necessary.

By providing a reliable, efficient, and scalable solution for SMT Printer line management, the MPM Edison II ACT is a forward-thinking tool that aligns with Industry 4.0 initiatives. Its intelligent design for accuracy, speed, and minimal intervention contributes to enhanced productivity, process reliability, and a progressive path toward a fully automated factory floor, positioning it as a valuable asset in advanced electronics manufacturing.

Automated Changeover Scope and capabilities

3 Paste cartridge

Dedicated tooling plate

2 Squeegees

Stencil

Integral scanner for verification

MES enabled

MPM solution differentiators

Adaptive

Easy to use, simple to adopt

Attractive ROI for users

Scalable

Baseline machine ACT upgradeable

Tiered offering – variety of use cases

Customer benefits

Error free and scrap free changeover

Labor and skill dependence reduction

Changeover time reduction

OEE improvements

#2 DEK Printer

DEK stencil printers are renowned for their modular design, allowing customization to meet specific production needs while retaining core features that ensure high performance. These printers facilitate flexible and efficient printing processes, adapting seamlessly to various PCB sizes and component types.

With advanced software integrated into the system, users benefit from intuitive controls and real-time monitoring, which enhance productivity and reduce errors during the printing process. The robust software supports features like automatic stencil alignment, solder paste inspection, and process optimization, ensuring consistent quality in every print.

Additionally, DEK’s commitment to competent support guarantees that users have access to expert assistance and maintenance, enhancing operational efficiency. Whether for high-volume production or low-mix environments, DEK stencil printers deliver reliability and precision, making them a preferred choice for manufacturers seeking to optimize their surface mount technology (SMT) assembly processes.

DEK NeoHorizon

Maximum flexibility for any volume

DEK NeoHorizon: maximum flexibility for any volumes. With its modular and scalable design, the DEK NeoHorizon series will meet all your needs – whether you run high-volume production or need high flexibility to handle even smallest lots – The DEK NeoHorizon printer combines highest demands on speed, efficiency and accuracy 2.

DEK NeoHorizon 03 iX:

- Machine Alignment Capability: ±12.5 µm @ 2.0 cmk, (±6 Sigma)

- System Alignment Capability: +/- 20μm @ 2.0 cmk, (±6 Sigma)

- Wet Print Capability: ±25 µm @ 2.0 cpk, (±6 Sigma) – Certified by external system for every printer before delivery by standard

- Core Cycle Time (CCT): 8 sec.

- Perfect printing solution for best performance in high-mix production

DEK NeoHorizon 01 iX:

- Machine Alignment Capability: ±12.5 µm @ 2.0 cmk, (±6 Sigma)

- System Alignment Capability: +/- 15μm @ 2.0 cmk, (±6 Sigma)

- Wet Print Capability: ±20 µm @ 2.0 cpk, (±6 Sigma) – Certified by external system for every printer before delivery by standard

- Core Cycle Time (CCT): 6.5 sec.

- Best printing quality with maximum throughput

DEK NeoHorizon Back-to-Back:

The DEK NeoHorizon Back-to-Back setup offers higher print performance in dual-lane assembly line.

#3 Gkg Printer

GKG Precision Machine Co., Ltd. is a national high-tech enterprise specializing on the R&D, production, sales, and process solutions of high-end precision automation equipment.

If you want to try something innovative with SMT Printer machines, Gkg Printer could be the best manufacturer for you to contact.

The GKG has an ongoing list of features that proves it a perfect SMT Printer machine manufacturer. Some of them are as follows:

Wide Range:GKG company has a division of precision solder paste printing equipment, a division of high-speed precision dispensing equipment, a division of precision packaging equipment, and a division of flexible manufacturing system.

Compatible Price: Despite being a big name GKG is budget-friendly; your budget does not matter; you will always have something from GKG that will surely meet your requirements.

#4 EKRA Printing Systems

At EKRA, we specialize in providing scalable printing systems tailored to enhance your electronics production capabilities. Our advanced stencil and screen printers are designed to apply solder paste to printed circuit boards (PCBs) with unmatched precision and repeatable accuracy. We understand the critical importance of accuracy in electronics manufacturing, where even minor deviations can lead to significant quality issues. That’s why we focus meticulously on every detail of our printing solutions, ensuring that they meet the high standards required for modern production environments.

Our commitment to customization means that we work closely with you to develop a solution that not only fits your current production needs but also adapts to future requirements. Whether you are engaged in 24/7 high-volume production or managing smaller series runs, our broad product portfolio can cater to every application. We offer a variety of printer models that range from high-speed systems for mass production to more flexible options suited for low-volume, high-mix environments.

With EKRA, you benefit from a collaborative approach. We guide you through the selection process to identify the printer that best aligns with your operational goals, ensuring you have the right technology in place to maximize efficiency and productivity. Our machines come equipped with advanced features such as automatic stencil cleaning, real-time monitoring, and process optimization, further enhancing reliability and reducing production downtime.

Additionally, SMT printer machines EKRA provides ongoing support and training, empowering your team to utilize our equipment effectively and maintain high production standards. By choosing EKRA, you are not just investing in a printer; you are partnering with a brand that prioritizes your success and is dedicated to delivering innovative solutions for the evolving demands of the electronics industry.

X5 Professional Optilign MultiCarrier

Gets the most out of it for you

The X5 Professional Optilign MultiCarrier extends SMT printer machines EKRA’s proven Optilign option. Now up to six product carriers or PCBs can be printed simultaneously. Productivity on the line increases with maximum print repeatability. Stretch problems are effectively eliminated thanks to the ingenious process. The stencil and squeegee blades have a reduced wear and tear, as more output is achieved in one printing process than with a conventional method. In addition, the consumption of cleaning paper, recalculated for the individual circuit, is reduced.

The Optilign MultiCarrier option is available for the X5 Professional printing system and can be easily integrated into an existing line concept. Many circuit board sizes and even individual circuit boards can be processed. Thus, the X5 Professional with Optilign MultiCarrier is ready for highly complex and standard applications.

SERIO 6000

Autonomy to Infinity

The SMT printer machines SERIO 6000 is the first fully automatic printer worldwide. The system offers automation in stages – adaptable to the automation level of the existing production. With the smart autonomous printer, squeegees and stencils can be set up asynchronously, for example. Specific tools for the next product cycle can be stored directly on the printer and then automatically installed at the right time. Set-up can be done manually by an operator or autonomously via a Cobot. The SMT printer machines SERIO 6000 is capable of operating over several shifts without significant operator intervention.

Discover the autonomous printer – adapted to your needs and easily integrated into your autonomous line or production.

#5 MINAMI

MINAMI, as a newly established commercial company, is on its way to becoming a leading company in printing technology. In doing so, we have inherited the technology of the former SMT printer machines MINAMI.

MINAMI’s business strategy consists of the following three areas. Completing the establishment of a management foundation and business development.

<Three business strategies

The first is printers for the SMT Printer market

The second is printers with ball bonder for the SEMI market.

The third is EMS subcontracting (SMT Printer) services

In addition, continue to provide maintenance support for former MINAMI machines from the perspective of customer satisfaction. Finally, MINAMI will continue to improve itself to ensure that it is a company that its customers, business partners, and employees can be proud of.

MK-888SV(MA)

Full automatic high speed screen printer with a visual recognition device.

It is a full spec machine capable of positioning multiple substrates simultaneously.

Product Outline

- Multiple substrates simultaneous printing function is added to the existing MK-888SV.

- Printing on multiple substrates can be performed simultaneously as a batch in high accuracy.

- It can handle BGA bump of Φ0.2mm, QFP with 0.3mm lead pitch and fine pattern with the world top class printing positioning repetitive accuracy (±0.015mm or less when image recognition is used).

- Position of multiple substrates (2〜desired number) is corrected one by one by a work positioning manipulator.

- Cartridge type detachable cleaning unit enables easy replacement of cleaning cotton.

- The cleaning unit can be switched between cotton type and adhesive tape type by one action.

#6 ESE

ESE delivers exceptional performance and quality in solder printing technology, positioning itself as a leader in the industry. Our advanced solder printing systems are designed to meet the stringent demands of modern electronics manufacturing, ensuring precise and reliable application of solder paste on printed circuit boards.

With innovative features and robust engineering, ESE printers enhance production efficiency and reduce defects, making them ideal for high-volume environments. Our commitment to excellence is reflected in our continuous advancements in technology, ensuring that customers receive top-tier solutions tailored to their unique production requirements.

Experience unparalleled quality and performance with SMT printer machines ESE’s cutting-edge solder printing technology.

ES-E2+

- High precise & Wet printing repeatability Printer

- 12 over enhanced standard program integrated

- Much solid frame & Table

- 3 stages conveyor system

- Auto stencil loading & Positioning

PCB Size

50㎜ x 50㎜ ~550㎜ x 510㎜

PCB Thickness

0.3㎜ ~ 6㎜

Stencil Mark Size

650mm, 736mm, 800mm, 850mm, 900mm

Cycle Time

9sec / under optimized condition

Alignment Accuracy

±10 ㎛ @ 6 sigma

Printing Repeatability

±20 ㎛ @ 6 sigma , Cpk ≥2.0

#7 INOTIS

INOTIS leads the industry by providing world-class technologies that revolutionize electronics manufacturing. Our innovative solutions are designed to enhance production efficiency, precision, and reliability across various applications. By leveraging cutting-edge automation and advanced software integration, SMT printer machines INOTIS ensures seamless operations and optimal performance for manufacturers.

Our commitment to quality and continuous improvement positions us at the forefront of the industry, enabling our clients to achieve their production goals and stay competitive in a rapidly evolving market. Choose SMT printer machines INOTIS for superior technologies that drive success and elevate your manufacturing processes to new heights.

X SERIES

3 Stage Conveyor System- Motorized Conveyor Width Adjustment- Reduce Waiting time for PCB transferring

Multi-Point PCB Clamping Block- Special Edge Clamping Control for Board Holding- Critical Part to Obtain Best Printing Quality

PCB Push-Down Unit- It Helps to Make PCB Flatness While Clamping- Critical Part to Obtain Best Printing Quality- It’s Very Useful Function for Big Size PCB to Clear Warpage

Edge Clamp by Motor- Controllable Clamping Distance- Minimize PCB Warpage by Controlling Clamping Distance

Solder Dispenser- Controllable Solder Drop Amount- Generate MES data

How to Choose the Best SMT Printer Machine?

Choosing the best SMT (Surface Mount Technology) printer machine is a critical decision that can significantly impact your manufacturing efficiency, product quality, and overall operational costs. Here are some key factors to consider when selecting the right SMT printer for your needs:

1. Production Volume and Scale

Determine the scale of your production. High-volume manufacturers may benefit from fully automated SMT printers that offer speed and efficiency, while smaller operations or prototyping labs might find semi-automatic or manual printers more suitable. Consider whether your production is continuous, batch-based, or requires frequent changeovers, as this will influence the type of printer that will best meet your needs.

2. Printer Type

SMT printers come in various types: manual, semi-automatic, and fully automatic. Manual printers are typically more affordable but require skilled operators for setup and operation. Semi-automatic printers offer a balance of automation and manual control, making them suitable for moderate production needs. Fully automatic printers are ideal for high-volume production, offering advanced features like automatic stencil alignment and paste inspection.

3. Precision and Accuracy

Look for printers that provide high precision and repeatability. Features such as ±8 micron alignment and ±15 micron wet print accuracy are essential for achieving tight tolerances, especially with smaller components like 0201 metrics. High accuracy ensures that solder paste is applied uniformly, reducing defects and rework costs.

4. Software and Integration

Evaluate the software capabilities of the SMT printer. Advanced software can enhance usability through intuitive interfaces, real-time monitoring, and process optimization. Consider whether the printer integrates easily with your existing manufacturing systems, such as PCB design software and assembly lines.

5. Support and Service

Reliable customer support is crucial for minimizing downtime and maintaining operational efficiency. Research the manufacturer’s reputation for service and support, including availability of training, spare parts, and technical assistance. A strong support system can significantly enhance the longevity and reliability of your investment.

6. Cost and Budget

While it can be tempting to choose the lowest-priced option, consider the total cost of ownership, including maintenance, consumables, and potential downtime. Investing in a high-quality printer may result in lower operational costs over time, thanks to improved efficiency and reduced error rates.

7. Flexibility and Scalability

Assess the printer’s ability to handle various PCB sizes, component types, and production volumes. A flexible printer that can adapt to changing production requirements will provide better long-term value. Scalability is also important for businesses anticipating growth or diversification in their product lines.

Choosing the best SMT printer involves a careful analysis of your specific production needs, budget, and long-term goals. By considering these factors, you can select an SMT printer that not only meets your current requirements but also supports future growth and innovation in your manufacturing processes. Investing in the right technology will ultimately enhance your production efficiency, product quality, and competitiveness in the marketplace.

Top SMT Printer Machine Brands according to the Location

1. United States

- DEK (by ASM Assembly Systems): Known for its high-precision stencil printers and automation solutions, DEK is a leading brand in SMT printing, offering machines suitable for high-volume production.

- MPM (by Speedline Technologies): MPM printers are renowned for their accuracy and advanced features like Automated Changeover Technology, making them ideal for high-density applications.

2. Germany

- EKRA: A well-respected brand in the SMT industry, EKRA provides scalable printing systems designed for precision and adaptability in electronics manufacturing.

- ASM Assembly Systems: Offers a wide range of SMT solutions, including high-quality printers and comprehensive assembly systems.

3. Japan

- MINAMI: Yamaha’s SMT printers are known for their innovative technology and high-speed capabilities, catering to a variety of production needs in electronics manufacturing.

- HITACHI: Panasonic SMT printers are recognized for their reliability and advanced features, focusing on high-speed printing and automation.

4. South Korea

- Hanwha Techwin: Specializes in SMT printing solutions with a focus on high-precision applications, catering to the growing electronics market in Korea and beyond.

- INOTIS: Known for its advanced SMT printing technology, Hanwha offers high-quality solutions for various production environments.

5. China

- GKG: A popular brand among small to medium-sized enterprises, Neoden offers affordable and versatile SMT printers that are suitable for prototyping and low-volume production.

- DESEN: Provides a range of SMT printing solutions, focusing on precision and efficiency, making it a competitive player in the Chinese electronics market.

6. Taiwan

- Vision Engineering: Offers innovative SMT printing technologies and systems that cater to various manufacturing needs, emphasizing flexibility and high performance.

- ESE: Known for its advanced solder printing technology, ESE is a prominent brand in the Taiwanese SMT market, focusing on high performance and quality.

7. Italy

- Fritsch: Specializes in SMT printers with a focus on high quality and flexibility, catering to a range of production environments in Europe and globally.

- SACMI: Offers a variety of printing solutions and technologies, focusing on efficiency and integration within the manufacturing process.

Conclusion

These brands represent some of the top players in the SMT printer market, each bringing unique strengths and innovations to the industry. When choosing an SMT printer, consider not only the brand but also the specific features, support services, and solutions they offer to best meet your production needs.