DEK PRINTER, Squeegee MPM MOMENTUM ; MPM 125 , MPM MOMENTUM BTB , MPM 100 , MPM EDISON , MPM MOMENTUM HIE ,SPEEDLINE , ITW EAE,MPM SPARE PARTS , MPM UP2000 , MPM ACCUFLEX,MPM ACCELA ,MPM AP EXCEL ,MPM AP , MPM UP3000 , MPM UP1500 , CAMALOT PRODIGY , CAMALOT 8300 , Camalot Dispensers , MPM PRINTER PARTS,GKG PRINTER ,DEK TQ , DEK NeoHorizon 03 iX ,Horizon 03 ix, 265 ,DEK NeoHorizon 01 iX

Squeegee blades are an intracule part of the print process.In a typical printing process, the

paste does not fill the aperture until the paste bead has traveled at least 75% beyond the

leading edge of the aperture. The aperture fills from the trailing edge of the aperture backwards.

It is the rolling of the solder paste bead that generates the downward force that drives the paste

to fill the aperture. This understanding of the aperture filling process is important to

understanding why the attack angle of the blade becomes critical.

Miniature components such as 01005 passives and 0.3 mm CSPs / BGAs demand the accuracy

and precise deposition of solder paste volume. It is well known that stencil printing is a complex

process, influenced by several variables that include hardware, software, materials and process

factors. Squeegee blade assembly happens to be an element of printing that can have a

significant effect on the print quality. Studies show most of the qualities are affected by

squeegee blade type and attack angle of the blade.

general, only two metal blade printing print parameters which affect aperture filling can be

controlled: squeegee speed and downward squeegee pressure. The speed should not be set so

high that the paste does not roll as it moves across the stencil or so low that the print cycle time

does not keep up with the manufacturing line. The blade pressure is usually set so that no paste

remains on the stencil behind the squeegee. Higher pressures will not only damage the stencil,

but also shear-thin the paste to such an extent that the flux will separate from the metal and

problems such as paste sticking to the blade, lack of tack at placement, or poor solder ability will

occur further down the assembly line.

What is the optimal squeegee blade assembly for a print process?

Below describe the following squeegee blade assemblies available for the current MPM printers:

Momentum series, Momentum II, and the Edison.Within each description there is a

recommended use as a starting point in selecting the correct squeegee blade assembly for the

print process.It’s possible a different blade type or angle maybe required to achieve optimal

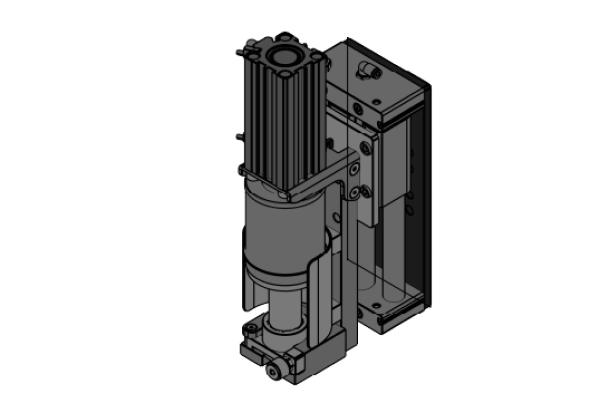

1023036-xxx:Currently the default blade assembly that’s being shipped with the Momentum

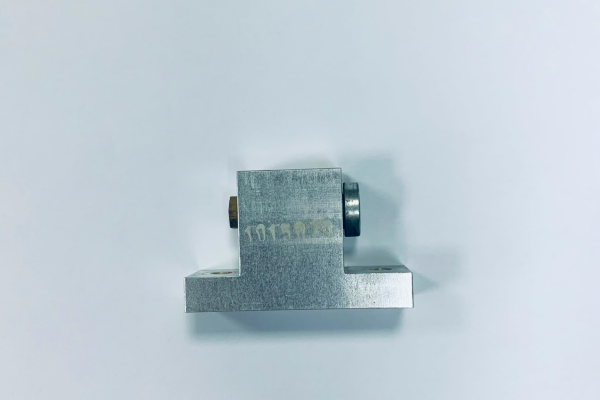

series printers. The blade holders have spring loaded floating side dams which keeps the paste

roll with in the squeegee blade area, reducing bleed out on the outside of the blades. The blade

holders are secured to the print head using a knob-screw.

Recommended use:This style blade assembly shows to have excellent print results on fine pitch

devices, (0201’s, 01005’s etc.) and micro BGA’s.

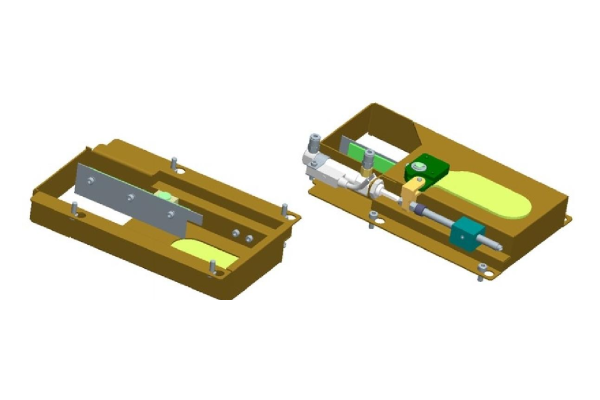

2006150-xxx:Currently the default blade assembly that’s being shipped with the Edison series

printers and will be used on Momentum II printers utilizing the Quick Release assembly. The

blade holders have spring loaded floating side dams which keeps the paste roll with in the

squeegee blade area, reducing bleed out on the outside of the blades. This assembly is like the

blade assembly 1023036, with a lower deflection point of the squeegee blade.

Recommended use:This style blade assembly shows to have excellent print results on fine pitch

devices, (0201’s, 01005’s etc.) and micro BGA’s.

1018140-xxx:Also,referred to as‘High Performance Squeegee’(HPS). This assembly comes

standard with a dual blade setup. The blade holders have spring loaded floating side dams which

keeps the paste roll within the squeegee blade area, reducing bleed out on the outside of the

blades. Utilizes the knob-screw post to mount to the print head. Single blade replacement is

available. This was the standard Momentum series printer blade assembly prior to 1023036-xxx.

This assembly is like the blade assembly 1024009, with a higher deflection point of the

Recommended use: Best results shown to be on larger devices (0201, 0402, 0603, etc.)

Excellent fill of the apertures. It also works well with finer pitch devices.

1024009-xxx:Is used on Edison printers only which utilizes the Quick Release feature. This

assembly is like the blade assembly 1018140, with a higher deflection point of the squeegee

blades. The blade holders have spring loaded floating side dams which keeps the paste roll with

in the squeegee blade area, reducing bleed out on the outside of the blades.This blade

assembly is comparable to the Accela style blade but the holder mounting is different.

Recommended use:Best results shown to be on larger devices (0201, 0402, 0603, etc.) with

excellent fill of the apertures.

1019813-xxx:The blade holders are set to a 55-degree angle. Due to the 55-degree angle, these

blades are for special applications. The blade holders have spring loaded floating side dams

which keeps the paste roll within the squeegee blade area, reducing bleed out on the outside of

the blades. Utilizes the knob-screw post to mount to the print head. Can be used on Edison

printers as well as the Momentum II printers utilizing the Quick Release feature by changing the

mounting hardware to locking pins. The blade holder shave spring loaded floating side dams

which keeps the paste roll with in the squeegee blade area, reducing bleed out on the outside of

Recommended use:To achieve slightly larger aperture fill (increase volume) for larger devices.

1024142-xxx:The blade holders are set to a 45-degree angle. Due to the 45-degree angle, these

blades are for special applications. Can be used on Edison printers as well as the Momentum II

printers utilizing the Quick Release feature. The blade holders have spring loaded floating side

dams which keeps the paste roll with in the squeegee blade area, reducing bleed out on the

Recommended use: The main requirements for Pin N Paste process is stencil & substrate

design. The 45-degree assembly can assist with larger aperture fill or thick stencils and Pin N

1006638-xxx:This is the original blade assembly for the Momentum printers. These were

replaced with 1018140 assembly. The blade holders do not have floating side dams. The side

dams must be adjusted manually. The blades have mounting holes to attach to the squeegee

holders.This assembly utilizes the knob –screw mounting.

Recommended use:Best results shown to be on larger devices (0201, 0402, 0603, etc.) with

excellent fill of the apertures.

Notes:

The following blade holder assemblies are similar with each other except on how they are

1018140 & 1024009 are the same(knob and screw mounting

1023036 & 2006150 are the same(Quick Release mounting)

All holders are interchangeable by switching out either the knob-screw posts with the Quick

Release location pins or visa-a-versa.

A recommended starting point for print force is 1.5 lbs. (0.68 kg) per inch of substrate length in

Our screwmount holders are available in Standard gold anodized aluminum and Lead-Free green anodized aluminum for easy identification. Squeegee holders have a 60º printing angle but are also offered in a 45º custom angle upon request.

Squeegee blade choices: premium, lead-free and economy metal blades (with and without holes) and polyurethane blades.

We provide a complete line of squeegee products and understencil wiping rolls for Momentum, Accuflex, SPM500, UP1500 and SMTech stencil printers. All products are manufactured to the OEM’s specifications and are available in both standard and custom.

The MPM Momentum Plus model of squeegee blades are specially designed to fit the Momentum Plus series of stencil printers. The squeegee holders match the original equipment manufacturers specifications from Speedline/MPM and are available in the standard lengths offered by the OEM, and also are available in custom lengths to suit the individual customer’s needs. Each squeegee holder is made from precision machined aluminum, and come complete with the mounting knobs. Blades comes in various sizes from 8 to 14 inch, 16 to 20 inch and 22 to 24 inch. Sold in sets of 2 and comes with the blades. Only need the blade? Contact us with your size, we sell all blades as a set or individually.

Blade Sizes

8 Inch MPM Momentum Plus Squeegee Blades, 10 Inch MPM Momentum Plus Squeegee Blades, 12 Inch MPM Momentum Plus Squeegee Blades, 14 Inch MPM Momentum Plus Squeegee Blades, 16 Inch MPM Momentum Plus Squeegee Blades, 18 Inch MPM Momentum Plus Squeegee Blades, 20 Inch MPM Momentum Plus Squeegee Blades, 22 Inch MPM Momentum Plus Squeegee Blades, 24 Inch MPM Momentum Plus Squeegee Blades

Squeegees

Manufactured to exacting standards, DEK squeegees are constructed of the highest quality materials to deliver optimal printing results. Different applications call for different squeegees and ASMPT’s portfolio of polyurethane and stainless steel options provide the right tool for the job.

The best solution for applications that contain a mix of large, standard and fine-pitch components, DEK Stainless steel squeegees are the most widely used squeegees for robust SMT processes.

- Available with two different angles and overhangs

- Preferred solution for heterogeneous printing or PCBs with unconfirmed flatness

- Wide pressure window for excellent consistency and minimal wear

The new generation of laser cut squeegees replacement blades ensuring an improved paste transfer with little to no paste smearing. Reduces both defect count and operator intervention.

- Reduced paste smear

- More consistent paste roll control

- Reduced cleaning frequency

- Short lead times

The most widely used for SMT printing with metal stencils, particularly for heterogeneous assemblies, DEK Stainless Steel squeegees are well-suited for applications that feature a mix of large, standard and fine-pitch components or in cases where PCB panel flatness cannot be confirmed.

- Available with two different overhangs

- Preferred solution for heterogeneous printing or PCBs with unconfirmed flatness

- Wide pressure window for excellent consistency and minimal wear

The profile of the deflectors and their construction ensures no paste migration during operation, therefore maintaining reliable performance from the first to last print. There is no set up required per product, so risk of stencil coining due to product changeover is eliminated. The deflectors can be removed from the assembly without the need of tools with the simple ‘clip-in’ design.

Features and benefits:

- Drastically reduction of paste wastage through much reduced tram lines.

- Fast Return on Invest because of much reduced paste wastage

- More consistent paste roll

- Reduced operator intervention

- Increased ease of cleaning

- Less risk of cross-contamination due to their enclosed system,ease of cleaning and ability to ‘clip’ in new deflectors per product.

DEK Polyurethane squeegees can be used for single thickness or multi-level stencil applications, as well as adhesive stencils and mesh or emulsion screen printing.

- Available in a hardness range up to 120 durometer

- Can be re-ground to maintain a sharp edge for the life of the squeegee

- High-quality material

- Satisfies multiple stencil printing application requirements

- DEK PumpPrint™ squeegees for glue printing in combination with DEK PumpPrint™ stencils

For glue printing with DEK PumpPrint™ stencils

- Length from 170mm – 535 mm

In addition to the standard stainless steel and rubber squeegees, ASMPT offers a variety of other types of squeegees for applications such as:

- Screen printing

- Wafer coating

Specific Length?

If you desire a specific length that is not on our dropdown menu, choose the nearest length (greater) than your desired length, then enter the mm length you desire.

Special Width?

Normally our holders use a 1.25inch (31.75mm) wide blade. If you like to have a different blade width, you may enter it and we will modify the blade accordingly.

Custom Angle?

Normally our holders use flat blades, and hold them at 60 degrees with respect to the Stencil. If you like a different angle, specify the angle, and we will put a bend in the blade to achieve the net angle you specify. For example, if you put 45, then we add a 15 degree angle facing backwards – which gives a net angle of 45 degrees between the blade and stencil.

on the Whole Blade?

Normally our MPM PRINTER Coating is applied to the Tip of the squeegee. This gives the maximum fatigue resistance. However, if you like to have the MPM PRINTER on the whole blade – you may select this option. * Note: the life of the blade may be shorter with this option due to increased embrittlement at the bend region.

Advanced Holder System includes recently upgraded Adaptor incorporating anti-reverse tabs – prevent backwards installation. Also includes (2) M6 Thumb Screws and Soft-Touch(TM) Articulating Paste Retainers.

GKG PRINTER Detailed Product Description

| Brand: | GKG | Part Name: | Squeegee Blade |

|---|---|---|---|

| Size: | 450mm/510mm | Material: | Stainless Metal |

| Machine: | G5 Machine | Origin: | China |

| High Light: | screen printer parts, dek spare parts | ||

GKG Squeegee 450mm/510mm For G5 Stencil Printer blade with holder

Detail Information:

Part Name: Squeegee

Size: 450mm, 510mm

Origin: China

Condition: Brand New

Brand: GKG

Machine: GKG G5 Machine

Solder Connection, in association with Tannlin Stencil Manufacturing, offers you quality replacement standard and speciality Squeegee Blades for all SMT Stencil Printers, Including DEK, EKRA, JUKI, GKG, MPM, PANA.

Tannlin has a long history in laser manufacturing of precision components and is a full service provider for solder paste stencils and printer blades using only the highest grade stainless , which ensures all edges are smooth, sharp and true and will remain so offering a long service life and low cost of ownership.

Simply send us a drawing of your required printer blade dimensions and we can supply new blades within a few days.

EKRA Squeegee Blades & Holders

EKRA squeegee blades are specially designed to fit the EKRA series of stencil printers. The squeegee holders match the original equipment manufacturers specifications and are available in the standard lengths offered by the OEM, and also are available in custom lengths to suit the individual customer’s needs. Each squeegee holder is made from precision machined aluminum, and come with the mounting knobs. Blades comes in various sizes from 200mm to 450mm. Sold in sets of 2 and comes with the blades. Only need the blades? Contact us with your size, we sell all squeegee blades as a set or individually.

MPM printers are engineered with proven technology that was built on our successful legacy MPM stencil printer machines. From new print head technology to vision system development, today’s leading Momentum series of stencil printers are ready to meet the most exacting manufacturing challenges.

About MPM

Founded in 1968 in Somerville, Massachusetts, MPM is known globally as a premier manufacturer of SMT printing equipment used in the printed circuit board assembly industry.

MPM has a long history of product and industry-wide successes. A leader in innovation and technology, MPM has issued over 400 patents. Many of these designs are industry standards and have become integral to the success of the world’s largest OEM and contract electronics manufacturers. MPM’s award winning technologies include: the Edison Stencil Printer, Open Apps which is MPM’s Industry 4.0 open architecture, Camalot Inside integrated dispensing system, EnclosedFlow print head, 2D inspection, parallel processing, and many more. A core competency of MPM has been to focus on technologies that provide process solutions for high-end demanding production environments 1.

Momentum® II BTB features a smaller footprint than the standard Momentum platform. Back-to-Back configuration allows dual lane processing for higher throughput without increasing line length or capital investment. Dual lane provides the flexibility to print multiple products in a single SMT line, such as top and bottom side, same side, or mother/ daughter boards making the BTB the most flexible model in the proven Momentum platform.

The MPM Momentum II stencil printer is a proven, highly productive printer platform with industry leading accuracy and repeatability (certified by third party). Enhanced technologies provide further improvement around machine productivity, yield, ease of use, and flexibility.

The new Momentum II HiE is a single-rail stencil printer with servo motors, rather than stepper motors, driving the vision system’s X, Y, and Z axes. Faster than steppers, servos drive the vision gantry at higher speed and thus increase throughput and cut cycle time, making the Hi-E an efficient high-volume printer. New features enable improvement in productivity, yield, versatility, and ease of use.

The Momentum II stencil printers are designed for high throughput and accuracy. MPM’s rigid frame is welded for low vibrations and major assemblies are driven by precision ball screws. This allows for higher repeatability and greater reliability over time.

Momentum II has an advanced print head featuring a high precision load cell with closed loop pressure control for precise and consistent squeegee force. Tighter performance tolerances mean consistent repeatability with higher yield.