Camalot Dispensers feature the Adapter 680 Pump from ITW EAE, an important component that enhances the versatility and performance of adhesive dispensing systems.

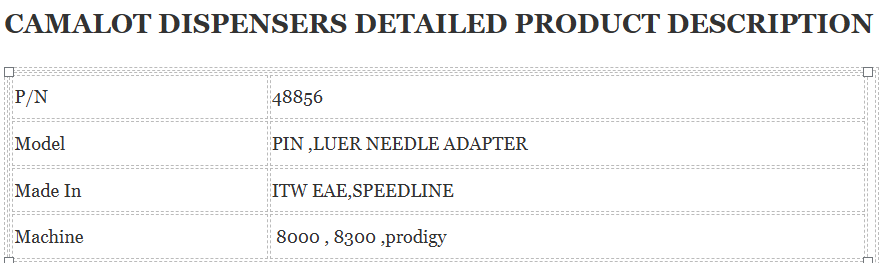

Overview of the 48856 Adapter 680 Pump

1. Functionality

The Adapter 680 Pump is designed to facilitate the efficient transfer and dispensing of various adhesive materials. It allows for precise control over the flow rate, making it suitable for a wide range of applications in manufacturing.