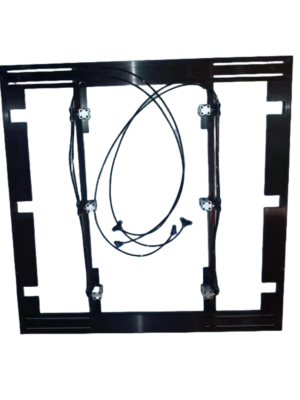

Origin New Mpm Printer 2005541 Motor ITW EAE

Mpm Printer 2005541 is essential for the proper functioning of the MPM printer, which is crucial for maintaining high print quality and printer reliability

mpm momentum screen printer 2005541 Motor from ITW EAE is engineered to deliver high torque and speed, making it an essential component for enhancing the performance of your MPM Stencil Printers. Investing in quality spare parts, such as the Momentum II 100 Stencil Printer motor, ensures optimal performance and longevity for your ITW EAE MPM Stencil Printers.